Aerospace Manufacturing Software

Aerospace Manufacturing SoftwareAerospace Manufacturing Software 2025 Trends and Forecasts 2033: Analyzing Growth Opportunities

Aerospace Manufacturing Software by Type (On Cloud, On Premise), by Application (Large Enterprises, SMEs), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

Base Year: 2024

149 Pages

Key Insights

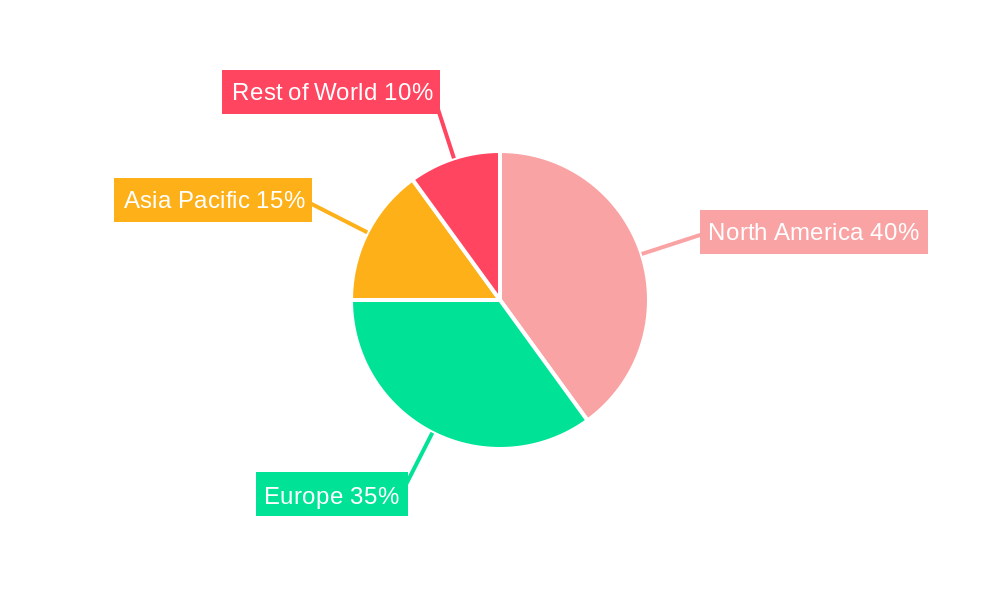

The aerospace manufacturing software market is experiencing robust growth, driven by the increasing demand for efficient and streamlined production processes within the aerospace industry. The sector's inherent complexity, coupled with stringent regulatory requirements, necessitates sophisticated software solutions for managing diverse aspects of manufacturing, including design, planning, production, and quality control. This demand is further fueled by the global rise in air travel and the subsequent need for more aircraft, pushing manufacturers to optimize their operations for higher efficiency and reduced costs. The market is segmented by deployment (on-cloud and on-premise) and user type (large enterprises and SMEs). On-cloud solutions are gaining traction due to their scalability, accessibility, and cost-effectiveness, while on-premise solutions remain prevalent among large enterprises prioritizing data security and control. SMEs are increasingly adopting cloud-based solutions to overcome resource limitations and access advanced functionalities. Competition is intense, with established players and emerging vendors vying for market share through innovation and strategic partnerships. Geographic growth varies, with North America and Europe holding significant market shares due to a concentrated presence of major aerospace manufacturers and established technology infrastructure. However, the Asia-Pacific region demonstrates substantial growth potential, driven by rapid industrialization and increasing investments in aerospace manufacturing. Future growth will be influenced by factors such as technological advancements (e.g., AI and IoT integration), regulatory changes, and fluctuating global economic conditions.

The market's Compound Annual Growth Rate (CAGR) signifies sustained expansion, indicating a positive outlook for the foreseeable future. While specific financial figures are not provided, a reasonable estimation of the 2025 market size, based on industry reports and considering typical growth rates within the software sector, could be placed in the range of $5-7 billion USD. This estimation incorporates the influence of the factors mentioned above, reflecting the market's overall health and momentum. Key players are leveraging strategic partnerships, acquisitions, and product development to maintain their competitive edge. Furthermore, the increasing integration of Industry 4.0 technologies such as AI and machine learning is poised to further enhance efficiency and automation within aerospace manufacturing, creating new avenues for software innovation and driving market expansion. The forecast period, 2025-2033, promises further market evolution, shaped by emerging trends and the continuous demand for improved aerospace manufacturing processes.

Aerospace Manufacturing Software Trends

The global aerospace manufacturing software market is experiencing robust growth, projected to reach multi-billion dollar valuations by 2033. The period from 2019 to 2024 (historical period) saw significant adoption of these solutions, driven by increasing complexities in aerospace manufacturing and the need for enhanced efficiency. The base year of 2025 marks a pivotal point, with the market demonstrating a clear shift towards cloud-based solutions and a growing demand from SMEs. This trend is expected to continue throughout the forecast period (2025-2033). Key market insights reveal a strong preference for integrated solutions that streamline processes across the entire manufacturing lifecycle, from design and planning to production and delivery. The demand for real-time data analytics and predictive maintenance capabilities is also significantly impacting the market's trajectory. This allows manufacturers to optimize resource allocation, reduce waste, and improve overall product quality. Furthermore, the increasing regulatory scrutiny in the aerospace sector is pushing companies to adopt software solutions that ensure compliance and traceability throughout the manufacturing process. The market is witnessing the emergence of specialized software tailored to address the unique needs of different aerospace manufacturing segments, fostering further growth and specialization. The integration of advanced technologies like AI and IoT within these software solutions is further accelerating market expansion, leading to improved decision-making, increased automation, and enhanced operational efficiency. This creates a significant competitive advantage for companies embracing digital transformation. The market is predicted to surpass several billion dollars by 2033.

Driving Forces: What's Propelling the Aerospace Manufacturing Software Market?

Several factors are propelling the growth of the aerospace manufacturing software market. The increasing complexity of aerospace products and manufacturing processes necessitates sophisticated software solutions to manage intricate supply chains, track materials, and ensure quality control. The demand for enhanced efficiency and productivity in aerospace manufacturing is a primary driver, as companies seek to reduce costs and improve turnaround times in a highly competitive market. The growing adoption of Industry 4.0 principles, including automation, data analytics, and the Internet of Things (IoT), is significantly influencing the market's expansion. These technologies enable real-time monitoring, predictive maintenance, and improved decision-making, leading to operational optimization and cost savings. Furthermore, stringent regulatory requirements and the need for complete traceability throughout the manufacturing process are pushing companies towards adopting software solutions that ensure compliance and minimize risks. The rising investments in research and development by both aerospace manufacturers and software providers are also contributing to innovation and the creation of advanced software solutions tailored to the specific needs of the industry. Finally, the increasing availability of cloud-based solutions is making these powerful tools more accessible and cost-effective for companies of all sizes, fostering wider adoption.

Challenges and Restraints in Aerospace Manufacturing Software

Despite the significant growth potential, the aerospace manufacturing software market faces several challenges. The high cost of implementation and maintenance of these software solutions can be a significant barrier to entry, particularly for smaller companies. The need for extensive training and expertise to effectively utilize these complex systems can also pose a challenge. Integrating new software solutions with existing legacy systems can be a complex and time-consuming process, requiring significant resources and expertise. Data security and privacy concerns are paramount in the aerospace industry, and ensuring the security of sensitive data within these software systems is critical. The need for ongoing updates and maintenance to keep pace with technological advancements can also pose a significant financial burden. Finally, the lack of standardized data formats and interoperability across different software platforms can hinder efficient data exchange and integration. Overcoming these challenges will be crucial for the continued growth and widespread adoption of aerospace manufacturing software.

Key Region or Country & Segment to Dominate the Market

The North American market is expected to dominate the aerospace manufacturing software market due to the presence of major aerospace manufacturers and a strong focus on technological advancements. The high concentration of large enterprises in the region further fuels the demand for sophisticated software solutions.

- North America: High adoption rates, established aerospace industry, and significant investments in technology.

- Europe: Strong presence of established aerospace companies and increasing focus on digitalization.

- Asia-Pacific: Rapid growth driven by increasing investments in aerospace manufacturing and a burgeoning SME segment.

Segment Domination: Large Enterprises

Large enterprises in the aerospace manufacturing sector are driving the demand for advanced software solutions. Their complex manufacturing processes, extensive supply chains, and stringent regulatory requirements necessitate sophisticated software to manage operations efficiently. The need for real-time data analytics, predictive maintenance capabilities, and seamless integration across various departments makes these advanced software solutions essential for maintaining a competitive edge. The high investment capacity of large enterprises facilitates the adoption of expensive, yet highly effective, solutions. This segment is expected to remain dominant throughout the forecast period.

In short: North America and large enterprises will significantly impact market growth.

Growth Catalysts in the Aerospace Manufacturing Software Industry

The increasing adoption of cloud-based solutions, the integration of advanced technologies like AI and IoT, and the growing demand for real-time data analytics are major catalysts for growth in the aerospace manufacturing software industry. These factors are driving efficiency improvements, cost reductions, and enhanced decision-making capabilities.

Leading Players in the Aerospace Manufacturing Software Market

- ERPAG

- Aegis Aegis

- Fishbowl Fishbowl

- Intrastage

- NetSuite NetSuite

- E2 Shop System

- JobBOSS

- Global Shop Solutions Global Shop Solutions

- Deskera ERP Deskera ERP

- OptiProERP

- ECi M1

- Priority

- LillyWorks

- KeyedIn Manufacturing

- Henning Visual EstiTrack ERP

- IQMS ERP Software IQMS ERP Software

- MIE Trak PRO

- Sage 100cloud Sage 100cloud

- COSS ERP

- Intellect eQMS

Significant Developments in the Aerospace Manufacturing Software Sector

- 2020: Several major aerospace manufacturers announced significant investments in digital transformation initiatives, including the adoption of advanced manufacturing software.

- 2021: Increased partnerships between aerospace companies and software providers to develop specialized solutions.

- 2022: Launch of several cloud-based aerospace manufacturing software platforms.

- 2023: Growing adoption of AI and machine learning in aerospace manufacturing software to improve predictive maintenance and optimize processes.

Comprehensive Coverage Aerospace Manufacturing Software Report

This report provides a detailed analysis of the aerospace manufacturing software market, covering historical data, current trends, and future projections. It offers valuable insights into the key drivers, challenges, and growth opportunities within the market, providing a comprehensive understanding of the market landscape and its potential for continued expansion. The report includes detailed profiles of leading players in the market, allowing for a deeper understanding of their market strategies and competitive landscape.

Aerospace Manufacturing Software Segmentation

-

1. Type

- 1.1. On Cloud

- 1.2. On Premise

-

2. Application

- 2.1. Large Enterprises

- 2.2. SMEs

Aerospace Manufacturing Software Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Aerospace Manufacturing Software REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Frequently Asked Questions

Table Of Content

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Aerospace Manufacturing Software Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. On Cloud

- 5.1.2. On Premise

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Large Enterprises

- 5.2.2. SMEs

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. North America Aerospace Manufacturing Software Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. On Cloud

- 6.1.2. On Premise

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Large Enterprises

- 6.2.2. SMEs

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. South America Aerospace Manufacturing Software Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. On Cloud

- 7.1.2. On Premise

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Large Enterprises

- 7.2.2. SMEs

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Europe Aerospace Manufacturing Software Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. On Cloud

- 8.1.2. On Premise

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Large Enterprises

- 8.2.2. SMEs

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Middle East & Africa Aerospace Manufacturing Software Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. On Cloud

- 9.1.2. On Premise

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Large Enterprises

- 9.2.2. SMEs

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Asia Pacific Aerospace Manufacturing Software Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Type

- 10.1.1. On Cloud

- 10.1.2. On Premise

- 10.2. Market Analysis, Insights and Forecast - by Application

- 10.2.1. Large Enterprises

- 10.2.2. SMEs

- 10.1. Market Analysis, Insights and Forecast - by Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 ERPAG

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Aegis

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Fishbowl

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Intrastage

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 NetSuite

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 E2 Shop System

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 JobBOSS

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Global Shop Solutions

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Deskera ERP

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 OptiProERP

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 ECi M1

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Priority

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 LillyWorks

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 KeyedIn Manufacturing

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.15 Henning Visual EstiTrack ERP

- 11.2.15.1. Overview

- 11.2.15.2. Products

- 11.2.15.3. SWOT Analysis

- 11.2.15.4. Recent Developments

- 11.2.15.5. Financials (Based on Availability)

- 11.2.16 IQMS ERP Software

- 11.2.16.1. Overview

- 11.2.16.2. Products

- 11.2.16.3. SWOT Analysis

- 11.2.16.4. Recent Developments

- 11.2.16.5. Financials (Based on Availability)

- 11.2.17 MIE Trak PRO

- 11.2.17.1. Overview

- 11.2.17.2. Products

- 11.2.17.3. SWOT Analysis

- 11.2.17.4. Recent Developments

- 11.2.17.5. Financials (Based on Availability)

- 11.2.18 Sage 100cloud

- 11.2.18.1. Overview

- 11.2.18.2. Products

- 11.2.18.3. SWOT Analysis

- 11.2.18.4. Recent Developments

- 11.2.18.5. Financials (Based on Availability)

- 11.2.19 COSS ERP

- 11.2.19.1. Overview

- 11.2.19.2. Products

- 11.2.19.3. SWOT Analysis

- 11.2.19.4. Recent Developments

- 11.2.19.5. Financials (Based on Availability)

- 11.2.20 Intellect eQMS

- 11.2.20.1. Overview

- 11.2.20.2. Products

- 11.2.20.3. SWOT Analysis

- 11.2.20.4. Recent Developments

- 11.2.20.5. Financials (Based on Availability)

- 11.2.21

- 11.2.21.1. Overview

- 11.2.21.2. Products

- 11.2.21.3. SWOT Analysis

- 11.2.21.4. Recent Developments

- 11.2.21.5. Financials (Based on Availability)

- 11.2.1 ERPAG

List of Figures

- Figure 1: Global Aerospace Manufacturing Software Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Aerospace Manufacturing Software Revenue (million), by Type 2024 & 2032

- Figure 3: North America Aerospace Manufacturing Software Revenue Share (%), by Type 2024 & 2032

- Figure 4: North America Aerospace Manufacturing Software Revenue (million), by Application 2024 & 2032

- Figure 5: North America Aerospace Manufacturing Software Revenue Share (%), by Application 2024 & 2032

- Figure 6: North America Aerospace Manufacturing Software Revenue (million), by Country 2024 & 2032

- Figure 7: North America Aerospace Manufacturing Software Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Aerospace Manufacturing Software Revenue (million), by Type 2024 & 2032

- Figure 9: South America Aerospace Manufacturing Software Revenue Share (%), by Type 2024 & 2032

- Figure 10: South America Aerospace Manufacturing Software Revenue (million), by Application 2024 & 2032

- Figure 11: South America Aerospace Manufacturing Software Revenue Share (%), by Application 2024 & 2032

- Figure 12: South America Aerospace Manufacturing Software Revenue (million), by Country 2024 & 2032

- Figure 13: South America Aerospace Manufacturing Software Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Aerospace Manufacturing Software Revenue (million), by Type 2024 & 2032

- Figure 15: Europe Aerospace Manufacturing Software Revenue Share (%), by Type 2024 & 2032

- Figure 16: Europe Aerospace Manufacturing Software Revenue (million), by Application 2024 & 2032

- Figure 17: Europe Aerospace Manufacturing Software Revenue Share (%), by Application 2024 & 2032

- Figure 18: Europe Aerospace Manufacturing Software Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Aerospace Manufacturing Software Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Aerospace Manufacturing Software Revenue (million), by Type 2024 & 2032

- Figure 21: Middle East & Africa Aerospace Manufacturing Software Revenue Share (%), by Type 2024 & 2032

- Figure 22: Middle East & Africa Aerospace Manufacturing Software Revenue (million), by Application 2024 & 2032

- Figure 23: Middle East & Africa Aerospace Manufacturing Software Revenue Share (%), by Application 2024 & 2032

- Figure 24: Middle East & Africa Aerospace Manufacturing Software Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Aerospace Manufacturing Software Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Aerospace Manufacturing Software Revenue (million), by Type 2024 & 2032

- Figure 27: Asia Pacific Aerospace Manufacturing Software Revenue Share (%), by Type 2024 & 2032

- Figure 28: Asia Pacific Aerospace Manufacturing Software Revenue (million), by Application 2024 & 2032

- Figure 29: Asia Pacific Aerospace Manufacturing Software Revenue Share (%), by Application 2024 & 2032

- Figure 30: Asia Pacific Aerospace Manufacturing Software Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Aerospace Manufacturing Software Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Aerospace Manufacturing Software Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Aerospace Manufacturing Software Revenue million Forecast, by Type 2019 & 2032

- Table 3: Global Aerospace Manufacturing Software Revenue million Forecast, by Application 2019 & 2032

- Table 4: Global Aerospace Manufacturing Software Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Aerospace Manufacturing Software Revenue million Forecast, by Type 2019 & 2032

- Table 6: Global Aerospace Manufacturing Software Revenue million Forecast, by Application 2019 & 2032

- Table 7: Global Aerospace Manufacturing Software Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Aerospace Manufacturing Software Revenue million Forecast, by Type 2019 & 2032

- Table 12: Global Aerospace Manufacturing Software Revenue million Forecast, by Application 2019 & 2032

- Table 13: Global Aerospace Manufacturing Software Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Aerospace Manufacturing Software Revenue million Forecast, by Type 2019 & 2032

- Table 18: Global Aerospace Manufacturing Software Revenue million Forecast, by Application 2019 & 2032

- Table 19: Global Aerospace Manufacturing Software Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Aerospace Manufacturing Software Revenue million Forecast, by Type 2019 & 2032

- Table 30: Global Aerospace Manufacturing Software Revenue million Forecast, by Application 2019 & 2032

- Table 31: Global Aerospace Manufacturing Software Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Aerospace Manufacturing Software Revenue million Forecast, by Type 2019 & 2032

- Table 39: Global Aerospace Manufacturing Software Revenue million Forecast, by Application 2019 & 2032

- Table 40: Global Aerospace Manufacturing Software Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Aerospace Manufacturing Software Revenue (million) Forecast, by Application 2019 & 2032

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

STEP 1 - Identification of Relevant Samples Size from Population Database

STEP 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Top-down and bottom-up approaches are used to validate the global market size and estimate the market size for manufactures, regional segemnts, product and application.

Note* : In applicable scenarios

STEP 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

STEP 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

Additionally after gathering mix and scattered data from wide range of sources, data is triangull- ated and correlated to come up with estimated figures which are further validated through primary mediums, or industry experts, opinion leader.

About Market Research Forecast

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.