AlMgSc Alloy Powder for Additive Manufacturing

AlMgSc Alloy Powder for Additive ManufacturingAlMgSc Alloy Powder for Additive Manufacturing Charting Growth Trajectories: Analysis and Forecasts 2025-2033

AlMgSc Alloy Powder for Additive Manufacturing by Type (Scandium Content, Scandium Content ≥0.6%, World AlMgSc Alloy Powder for Additive Manufacturing Production ), by Application (Aerospace, Transportation, Others, World AlMgSc Alloy Powder for Additive Manufacturing Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

Key Insights

The AlMgSc alloy powder for additive manufacturing market has witnessed significant growth in recent years, reaching a market size of XXX million in 2023. The market is projected to expand at a CAGR of XX% during the forecast period of 2023-2033, driven by rising demand for high-performance alloys in aerospace and transportation applications. Key trends influencing the market include the increasing adoption of additive manufacturing technologies, advancements in materials science, and the growing focus on lightweight and durable materials.

Company profiles, regional analysis, and historical data for the period 2019-2024 are included in the market study. It also includes forecasts for the period 2025-2033, with a base year of 2025. The study covers various segments such as scandium content, application, and region, providing a comprehensive view of the AlMgSc alloy powder for additive manufacturing market.

AlMgSc Alloy Powder for Additive Manufacturing Trends

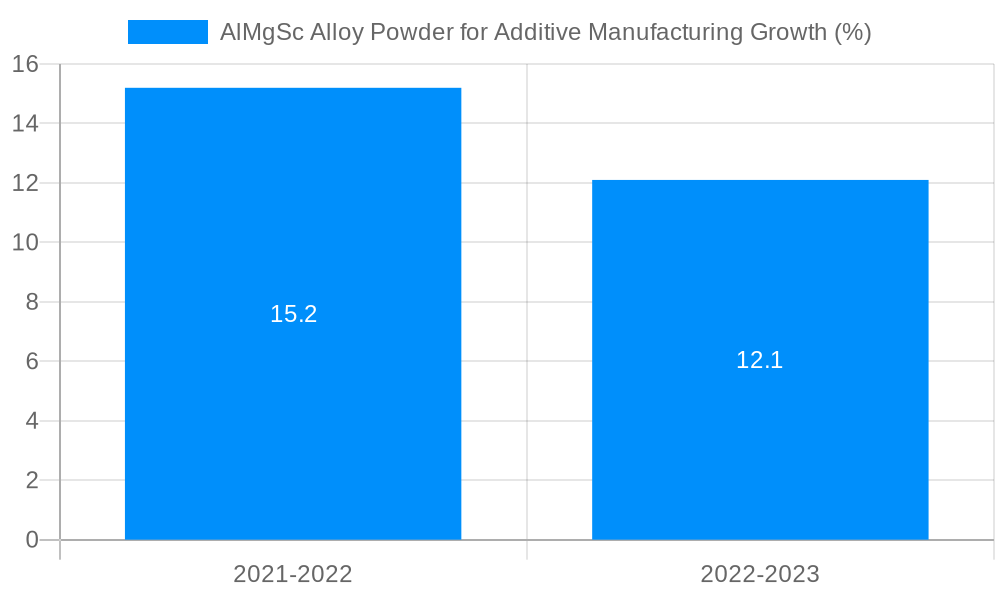

AlMgSc alloy powders for additive manufacturing (AM) have gained significant traction in recent years, owing to their superior properties and suitability for advanced applications. The global market for AlMgSc alloy powders for AM is estimated to reach over USD 300 million by 2025, growing at a CAGR of approximately 20% from 2021 to 2025.

This growth is primarily driven by the increasing demand for lightweight, high-strength materials in aerospace, transportation, and other industries. AlMgSc alloy powders offer exceptional specific strength, superior weldability, and high corrosion resistance, making them ideal for fabricating complex and lightweight components.

Driving Forces: What's Propelling the AlMgSc Alloy Powder for Additive Manufacturing

The growth of the AlMgSc alloy powder for AM market is attributed to several key factors:

Rising Adoption of Additive Manufacturing: AM technologies, such as selective laser melting (SLM) and electron beam melting (EBM), are gaining popularity due to their ability to produce complex geometries and reduce waste. AlMgSc alloy powders are highly compatible with these technologies, enabling the production of high-quality components with intricate designs.

Stringent Regulations on Emissions: Growing environmental concerns and regulations have led to a shift toward lightweight materials in transportation and other industries. AlMgSc alloy powders offer a lightweight alternative to traditional materials, reducing fuel consumption and emissions.

Increasing Demand for Advanced Materials: The advancements in various industries, including aerospace and automotive, demand materials with enhanced properties such as strength, durability, and corrosion resistance. AlMgSc alloy powders meet these requirements, making them a suitable choice for fabricating critical components.

Challenges and Restraints in AlMgSc Alloy Powder for Additive Manufacturing

Despite the growth potential, the AlMgSc alloy powder for AM market faces some challenges:

Cost of Production: Currently, the production of AlMgSc alloy powders is relatively expensive. However, as the demand increases and production technologies improve, the cost is expected to decline.

Quality Control: The AM process requires consistent powder quality to ensure the integrity and performance of the fabricated components. Maintaining high-quality standards in AlMgSc alloy powders is crucial but challenging due to the complex metallurgy and stringent requirements.

Lack of Standardization: There is a lack of standardized specifications and guidelines for AlMgSc alloy powders used in AM. Establishing industry-wide standards will help ensure product quality and traceability.

Key Region or Country & Segment to Dominate the Market

Key Region: North America

North America is the leading region in the AlMgSc alloy powder for AM market, driven by the presence of major aerospace companies, strong government support for advanced manufacturing, and a well-developed supply chain.

Dominating Segment: Aerospace

The aerospace industry is the primary consumer of AlMgSc alloy powders for AM, utilizing them to fabricate lightweight, high-strength components for aircraft, satellites, and spacecraft. The demand is expected to remain high as the industry continues to focus on fuel efficiency and performance enhancements.

Growth Catalysts in AlMgSc Alloy Powder for Additive Manufacturing Industry

Several key factors are expected to drive the growth of the AlMgSc alloy powder for AM industry:

Technological Innovations: Advancements in AM technologies, such as multi-beam SLM and hybrid processes, will enable the production of complex and highly customized components with AlMgSc alloy powders.

Government Support: Governments worldwide are investing in research and development to advance AM technologies and the adoption of lightweight materials.

Growing Demand from Emerging Industries: Emerging industries such as robotics, healthcare, and renewable energy are expected to create new growth opportunities for AlMgSc alloy powders in AM applications.

Leading Players in the AlMgSc Alloy Powder for Additive Manufacturing

Significant Developments in AlMgSc Alloy Powder for Additive Manufacturing Sector

Development of High-Performance AlMgSc Alloys: Researchers are developing new AlMgSc alloys with optimized compositions and heat treatments to enhance their mechanical properties and processability.

Hybrid Manufacturing Processes: Integrating AM with other manufacturing techniques, such as casting and forming, can improve the productivity and efficiency of AlMgSc alloy component production.

Advancements in Powder Characterization: Improved powder characterization techniques, such as in-situ X-ray tomography, help optimize the powder properties and ensure consistent quality in AM processes.

Comprehensive Coverage AlMgSc Alloy Powder for Additive Manufacturing Report

This comprehensive report provides an in-depth analysis of the global AlMgSc alloy powder for AM market, covering key trends, driving forces, challenges, and growth opportunities. It includes regional and segment-wise analysis, profiles of leading players, and insights into the latest developments and innovations in the industry.

AlMgSc Alloy Powder for Additive Manufacturing Segmentation

-

1. Type

- 1.1. Scandium Content

- 1.2. Scandium Content ≥0.6%

- 1.3. World AlMgSc Alloy Powder for Additive Manufacturing Production

-

2. Application

- 2.1. Aerospace

- 2.2. Transportation

- 2.3. Others

- 2.4. World AlMgSc Alloy Powder for Additive Manufacturing Production

AlMgSc Alloy Powder for Additive Manufacturing Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

AlMgSc Alloy Powder for Additive Manufacturing REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Frequently Asked Questions

How do I determine which pricing option suits my needs best?

The pricing options vary based on user requirements and access needs. Individual users may opt for single-user licenses, while businesses requiring broader access may choose multi-user or enterprise licenses for cost-effective access to the report.

What are the notable trends driving market growth?

.

Which companies are prominent players in the AlMgSc Alloy Powder for Additive Manufacturing?

Key companies in the market include APWORKS GmbH,Oriental Scandium

How can I stay updated on further developments or reports in the AlMgSc Alloy Powder for Additive Manufacturing?

To stay informed about further developments, trends, and reports in the AlMgSc Alloy Powder for Additive Manufacturing, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

Can you provide details about the market size?

The market size is estimated to be USD XXX million as of 2022.

Are there any specific market keywords associated with the report?

Yes, the market keyword associated with the report is "AlMgSc Alloy Powder for Additive Manufacturing," which aids in identifying and referencing the specific market segment covered.

What is the projected Compound Annual Growth Rate (CAGR) of the AlMgSc Alloy Powder for Additive Manufacturing ?

The projected CAGR is approximately XX%.

Are there any additional resources or data provided in the report?

While the report offers comprehensive insights, it's advisable to review the specific contents or supplementary materials provided to ascertain if additional resources or data are available.

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global AlMgSc Alloy Powder for Additive Manufacturing Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Scandium Content

- 5.1.2. Scandium Content ≥0.6%

- 5.1.3. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Aerospace

- 5.2.2. Transportation

- 5.2.3. Others

- 5.2.4. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. North America AlMgSc Alloy Powder for Additive Manufacturing Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Scandium Content

- 6.1.2. Scandium Content ≥0.6%

- 6.1.3. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Aerospace

- 6.2.2. Transportation

- 6.2.3. Others

- 6.2.4. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. South America AlMgSc Alloy Powder for Additive Manufacturing Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Scandium Content

- 7.1.2. Scandium Content ≥0.6%

- 7.1.3. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Aerospace

- 7.2.2. Transportation

- 7.2.3. Others

- 7.2.4. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Europe AlMgSc Alloy Powder for Additive Manufacturing Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Scandium Content

- 8.1.2. Scandium Content ≥0.6%

- 8.1.3. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Aerospace

- 8.2.2. Transportation

- 8.2.3. Others

- 8.2.4. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Scandium Content

- 9.1.2. Scandium Content ≥0.6%

- 9.1.3. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Aerospace

- 9.2.2. Transportation

- 9.2.3. Others

- 9.2.4. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Type

- 10.1.1. Scandium Content

- 10.1.2. Scandium Content ≥0.6%

- 10.1.3. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 10.2. Market Analysis, Insights and Forecast - by Application

- 10.2.1. Aerospace

- 10.2.2. Transportation

- 10.2.3. Others

- 10.2.4. World AlMgSc Alloy Powder for Additive Manufacturing Production

- 10.1. Market Analysis, Insights and Forecast - by Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 APWORKS GmbH

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Oriental Scandium

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.1 APWORKS GmbH

- Figure 1: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: Global AlMgSc Alloy Powder for Additive Manufacturing Volume Breakdown (K, %) by Region 2024 & 2032

- Figure 3: North America AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Type 2024 & 2032

- Figure 4: North America AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Type 2024 & 2032

- Figure 5: North America AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Type 2024 & 2032

- Figure 6: North America AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Type 2024 & 2032

- Figure 7: North America AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Application 2024 & 2032

- Figure 8: North America AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Application 2024 & 2032

- Figure 9: North America AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Application 2024 & 2032

- Figure 10: North America AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Application 2024 & 2032

- Figure 11: North America AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Country 2024 & 2032

- Figure 12: North America AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Country 2024 & 2032

- Figure 13: North America AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Country 2024 & 2032

- Figure 14: North America AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Country 2024 & 2032

- Figure 15: South America AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Type 2024 & 2032

- Figure 16: South America AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Type 2024 & 2032

- Figure 17: South America AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Type 2024 & 2032

- Figure 18: South America AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Type 2024 & 2032

- Figure 19: South America AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Application 2024 & 2032

- Figure 20: South America AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Application 2024 & 2032

- Figure 21: South America AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Application 2024 & 2032

- Figure 22: South America AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Application 2024 & 2032

- Figure 23: South America AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Country 2024 & 2032

- Figure 24: South America AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Country 2024 & 2032

- Figure 25: South America AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Country 2024 & 2032

- Figure 26: South America AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Country 2024 & 2032

- Figure 27: Europe AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Type 2024 & 2032

- Figure 28: Europe AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Type 2024 & 2032

- Figure 29: Europe AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Type 2024 & 2032

- Figure 30: Europe AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Type 2024 & 2032

- Figure 31: Europe AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Application 2024 & 2032

- Figure 32: Europe AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Application 2024 & 2032

- Figure 33: Europe AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Application 2024 & 2032

- Figure 34: Europe AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Application 2024 & 2032

- Figure 35: Europe AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Country 2024 & 2032

- Figure 36: Europe AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Country 2024 & 2032

- Figure 37: Europe AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Country 2024 & 2032

- Figure 38: Europe AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Country 2024 & 2032

- Figure 39: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Type 2024 & 2032

- Figure 40: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Type 2024 & 2032

- Figure 41: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Type 2024 & 2032

- Figure 42: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Type 2024 & 2032

- Figure 43: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Application 2024 & 2032

- Figure 44: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Application 2024 & 2032

- Figure 45: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Application 2024 & 2032

- Figure 46: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Application 2024 & 2032

- Figure 47: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Country 2024 & 2032

- Figure 48: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Country 2024 & 2032

- Figure 49: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Country 2024 & 2032

- Figure 50: Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Country 2024 & 2032

- Figure 51: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Type 2024 & 2032

- Figure 52: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Type 2024 & 2032

- Figure 53: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Type 2024 & 2032

- Figure 54: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Type 2024 & 2032

- Figure 55: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Application 2024 & 2032

- Figure 56: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Application 2024 & 2032

- Figure 57: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Application 2024 & 2032

- Figure 58: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Application 2024 & 2032

- Figure 59: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Revenue (million), by Country 2024 & 2032

- Figure 60: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Volume (K), by Country 2024 & 2032

- Figure 61: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Revenue Share (%), by Country 2024 & 2032

- Figure 62: Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Volume Share (%), by Country 2024 & 2032

- Table 1: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Region 2019 & 2032

- Table 3: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Type 2019 & 2032

- Table 4: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Type 2019 & 2032

- Table 5: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Application 2019 & 2032

- Table 7: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Region 2019 & 2032

- Table 8: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Region 2019 & 2032

- Table 9: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Type 2019 & 2032

- Table 10: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Type 2019 & 2032

- Table 11: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Application 2019 & 2032

- Table 13: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Country 2019 & 2032

- Table 14: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Country 2019 & 2032

- Table 15: United States AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: United States AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 17: Canada AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 18: Canada AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 19: Mexico AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 20: Mexico AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 21: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Type 2019 & 2032

- Table 22: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Type 2019 & 2032

- Table 23: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Application 2019 & 2032

- Table 24: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Application 2019 & 2032

- Table 25: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Country 2019 & 2032

- Table 26: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Country 2019 & 2032

- Table 27: Brazil AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Brazil AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 29: Argentina AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 30: Argentina AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 31: Rest of South America AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 32: Rest of South America AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 33: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Type 2019 & 2032

- Table 34: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Type 2019 & 2032

- Table 35: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Application 2019 & 2032

- Table 36: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Application 2019 & 2032

- Table 37: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Country 2019 & 2032

- Table 38: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Country 2019 & 2032

- Table 39: United Kingdom AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 40: United Kingdom AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 41: Germany AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: Germany AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 43: France AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: France AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 45: Italy AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Italy AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 47: Spain AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 48: Spain AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 49: Russia AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 50: Russia AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 51: Benelux AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 52: Benelux AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 53: Nordics AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 54: Nordics AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 55: Rest of Europe AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 56: Rest of Europe AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 57: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Type 2019 & 2032

- Table 58: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Type 2019 & 2032

- Table 59: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Application 2019 & 2032

- Table 60: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Application 2019 & 2032

- Table 61: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Country 2019 & 2032

- Table 62: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Country 2019 & 2032

- Table 63: Turkey AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 64: Turkey AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 65: Israel AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 66: Israel AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 67: GCC AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 68: GCC AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 69: North Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 70: North Africa AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 71: South Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 72: South Africa AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 73: Rest of Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 74: Rest of Middle East & Africa AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 75: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Type 2019 & 2032

- Table 76: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Type 2019 & 2032

- Table 77: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Application 2019 & 2032

- Table 78: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Application 2019 & 2032

- Table 79: Global AlMgSc Alloy Powder for Additive Manufacturing Revenue million Forecast, by Country 2019 & 2032

- Table 80: Global AlMgSc Alloy Powder for Additive Manufacturing Volume K Forecast, by Country 2019 & 2032

- Table 81: China AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 82: China AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 83: India AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 84: India AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 85: Japan AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 86: Japan AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 87: South Korea AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 88: South Korea AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 89: ASEAN AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 90: ASEAN AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 91: Oceania AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 92: Oceania AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

- Table 93: Rest of Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Revenue (million) Forecast, by Application 2019 & 2032

- Table 94: Rest of Asia Pacific AlMgSc Alloy Powder for Additive Manufacturing Volume (K) Forecast, by Application 2019 & 2032

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

STEP 1 - Identification of Relevant Samples Size from Population Database

STEP 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note* : In applicable scenarios

STEP 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

STEP 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

Related Reports

About Market Research Forecast

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.