Copper Centrifugal Casting

Copper Centrifugal CastingCopper Centrifugal Casting Strategic Insights: Analysis 2025 and Forecasts 2033

Copper Centrifugal Casting by Type (Die Casting, Melting and Casting, World Copper Centrifugal Casting Production ), by Application (Automobile Industry, Ship Industry, Machine Made, Others, World Copper Centrifugal Casting Production ), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

Key Insights

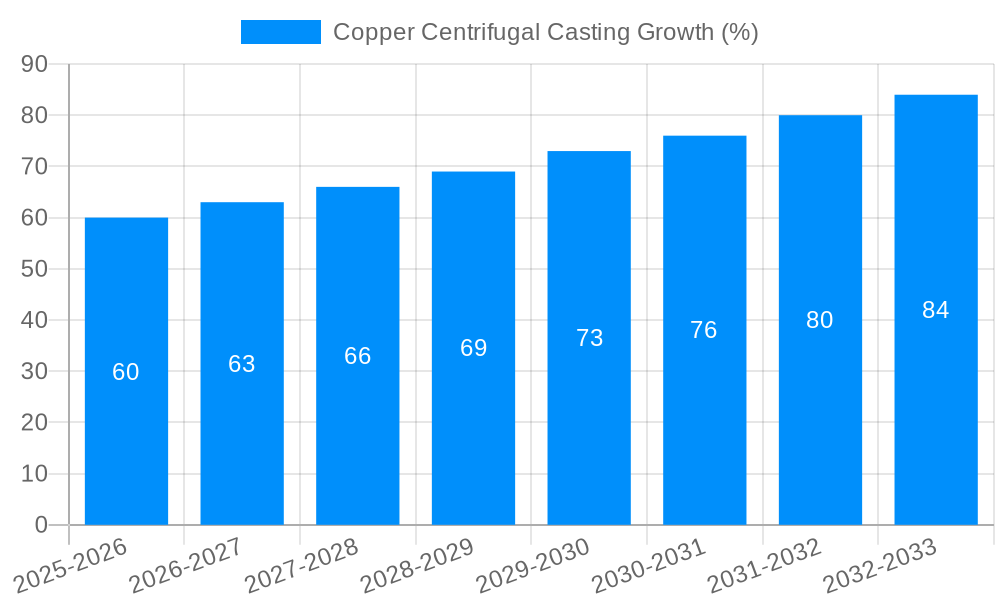

The global copper centrifugal casting market is experiencing robust growth, driven by increasing demand from key sectors like automotive and shipbuilding. The rising adoption of lightweight and high-strength materials in vehicles and vessels is a major catalyst, pushing manufacturers to explore cost-effective and efficient casting techniques. Copper's inherent properties, including excellent conductivity and corrosion resistance, make centrifugal casting a particularly attractive method for producing complex components with precise tolerances. The market is segmented by type (die casting, melting and casting) and application (automotive, shipbuilding, machinery, others). While precise figures for market size and CAGR are unavailable from the provided text, industry analysis suggests a market size exceeding $1 billion in 2025, with a healthy CAGR of around 5-7% projected through 2033. This growth trajectory is further fueled by ongoing technological advancements in centrifugal casting processes, leading to enhanced productivity and improved product quality. The increasing adoption of automation and precision manufacturing technologies within the casting industry is expected to further propel market expansion.

However, the market faces challenges including fluctuating copper prices, which can impact profitability, and the need for skilled labor to operate sophisticated centrifugal casting equipment. Regional variations in market growth are anticipated, with Asia Pacific (particularly China and India) leading the way due to rapid industrialization and substantial automotive production. North America and Europe are also expected to show healthy growth, driven by technological innovation and the replacement of existing infrastructure. Companies operating in this space range from established players with extensive experience in metal casting to smaller, specialized firms focusing on niche applications. The competitive landscape is characterized by a mix of regional and global players, highlighting opportunities for both large-scale production and specialized services.

Copper Centrifugal Casting Trends

The global copper centrifugal casting market, valued at approximately $XXX million in 2025, is poised for significant growth during the forecast period (2025-2033). Driven by increasing demand from key sectors like automotive and shipbuilding, the market is witnessing a steady transition towards advanced casting techniques and materials. The historical period (2019-2024) saw a gradual increase in production, with notable contributions from established players like Tallman Technologies and Conex Casting. However, the estimated year (2025) marks a potential inflection point, with several factors contributing to accelerated growth. These include the rising adoption of lightweighting strategies in vehicle manufacturing, leading to increased demand for high-strength copper alloys, and the ongoing expansion of the global shipbuilding industry. Furthermore, advancements in centrifugal casting technology are allowing for the production of more complex and precise components, opening up new application possibilities in machinery and other sectors. The market is also witnessing a trend towards the adoption of sustainable practices, with companies increasingly focusing on reducing their environmental footprint through efficient energy consumption and waste management strategies. This trend, combined with technological advancements and rising global demand, positions the copper centrifugal casting market for substantial growth in the coming years. The competitive landscape is characterized by a mix of large multinational corporations and smaller specialized players, each vying for market share through product innovation and strategic partnerships. The market's future growth is contingent on several factors, including raw material prices, global economic conditions, and technological developments in casting technologies.

Driving Forces: What's Propelling the Copper Centrifugal Casting Market?

Several key factors are driving the expansion of the copper centrifugal casting market. The automotive industry's unwavering focus on lightweighting vehicles to enhance fuel efficiency and performance is a primary driver. Copper alloys, with their unique combination of strength, conductivity, and corrosion resistance, are increasingly favored for various automotive components, fueling demand for centrifugal casting. Similarly, the shipbuilding industry's growth, particularly in the construction of larger and more technologically advanced vessels, creates substantial demand for high-quality copper castings for marine applications. Furthermore, advancements in centrifugal casting technology, such as improved precision and automation, enable the cost-effective production of intricate components previously impossible or prohibitively expensive to manufacture. This increased efficiency translates to greater adoption across diverse industries, including machinery and equipment manufacturing. Finally, the growing emphasis on sustainable manufacturing practices is encouraging the use of recyclable copper alloys, contributing to the market's overall positive outlook. This convergence of technological advancements, industrial demands, and sustainability concerns promises sustained growth for the copper centrifugal casting market throughout the forecast period.

Challenges and Restraints in Copper Centrifugal Casting

Despite the promising growth prospects, the copper centrifugal casting market faces several challenges. Fluctuations in copper prices represent a significant risk, directly impacting production costs and profitability. The market is also sensitive to global economic conditions; any slowdown in key industries, like automotive and shipbuilding, can dampen demand. Competition from alternative casting methods and materials, such as aluminum and plastics, poses another significant obstacle. These alternatives often offer lower costs or specific material properties that might be advantageous in certain applications. Furthermore, the skilled labor required for intricate centrifugal casting processes can be scarce, leading to potential production bottlenecks. Finally, stringent environmental regulations regarding emissions and waste management add another layer of complexity and cost to manufacturing operations. Successfully navigating these challenges will be crucial for sustained growth and profitability in the copper centrifugal casting market.

Key Region or Country & Segment to Dominate the Market

The automotive industry segment is projected to hold a dominant position in the copper centrifugal casting market during the forecast period. The increasing demand for lightweight and high-performance vehicles is driving the adoption of copper alloys in various automotive components, including brake components, engine parts, and electrical connectors. Geographically, regions with significant automotive manufacturing hubs are expected to show substantial growth.

North America: This region benefits from a strong domestic automotive industry, coupled with technological advancements in centrifugal casting. Companies in the US and Canada are actively investing in enhancing their production capabilities.

Europe: The European market is characterized by stringent environmental regulations, which are driving the adoption of lightweight materials like copper alloys in vehicles.

Asia-Pacific: The rapid growth of the automotive industry in China and other Asian countries is a major factor driving market expansion in this region.

Germany: A major player in the global automotive sector. The country's strong industrial base and focus on innovation contribute significantly to market growth.

Japan: Known for its sophisticated manufacturing processes and technological advancements, Japan's contribution to the market is considerable.

The Automobile Industry application segment is expected to dominate due to increasing demand for lightweight vehicles and stringent fuel efficiency standards. The demand for copper centrifugal castings in automotive applications is further fueled by the growing adoption of electric and hybrid vehicles, which require specialized copper components for efficient energy management and high-voltage systems. The increase in demand from this segment will be a significant driver of market growth for the forecast period.

Growth Catalysts in the Copper Centrifugal Casting Industry

Several factors are expected to propel the growth of the copper centrifugal casting industry. The increasing demand for lightweight and high-strength components in various industries, coupled with advancements in casting technology that enable the production of complex and precise parts, is a major catalyst. Moreover, rising investment in research and development for novel copper alloys with improved properties is fostering innovation and expanding the applications of copper centrifugal castings. The automotive industry's focus on sustainability is also a major driver, as copper is a recyclable material that aligns with environmental goals.

Leading Players in the Copper Centrifugal Casting Market

- Tallman Technologies

- Electric Materials

- Conex Casting

- Anchor Bronze & Metals

- Conex Metals

- Kigema

- Johnson Centrifugal Technology

- Delta Centrifugal

- NISARG CASTING

- Vaishnavi Metal Products

- Les Bronzes d'Industrie (LBI)

- Wisconsin Centrifugal Division

- Bunty LLC

- Bronze Foundry & Machine

Significant Developments in the Copper Centrifugal Casting Sector

- 2022: Johnson Centrifugal Technology announces a new investment in automated casting technology.

- 2021: Tallman Technologies partners with a major automotive manufacturer to develop a new line of copper alloy components.

- 2020: Conex Casting introduces a new high-strength copper alloy optimized for marine applications.

- 2019: Electric Materials invests in research and development of sustainable copper casting processes.

Comprehensive Coverage Copper Centrifugal Casting Report

This report provides a comprehensive overview of the copper centrifugal casting market, offering valuable insights into market trends, growth drivers, challenges, and key players. The detailed analysis covers the historical period (2019-2024), the base year (2025), and the forecast period (2025-2033), providing a holistic understanding of the market’s trajectory. The report segments the market by type, application, and geography, enabling readers to identify promising investment opportunities and navigate the evolving landscape of this dynamic industry. It also includes detailed profiles of leading companies, highlighting their market strategies and competitive positioning.

Copper Centrifugal Casting Segmentation

-

1. Type

- 1.1. Die Casting

- 1.2. Melting and Casting

- 1.3. World Copper Centrifugal Casting Production

-

2. Application

- 2.1. Automobile Industry

- 2.2. Ship Industry

- 2.3. Machine Made

- 2.4. Others

- 2.5. World Copper Centrifugal Casting Production

Copper Centrifugal Casting Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Copper Centrifugal Casting REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Copper Centrifugal Casting Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Die Casting

- 5.1.2. Melting and Casting

- 5.1.3. World Copper Centrifugal Casting Production

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Automobile Industry

- 5.2.2. Ship Industry

- 5.2.3. Machine Made

- 5.2.4. Others

- 5.2.5. World Copper Centrifugal Casting Production

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. North America Copper Centrifugal Casting Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Die Casting

- 6.1.2. Melting and Casting

- 6.1.3. World Copper Centrifugal Casting Production

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Automobile Industry

- 6.2.2. Ship Industry

- 6.2.3. Machine Made

- 6.2.4. Others

- 6.2.5. World Copper Centrifugal Casting Production

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. South America Copper Centrifugal Casting Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Die Casting

- 7.1.2. Melting and Casting

- 7.1.3. World Copper Centrifugal Casting Production

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Automobile Industry

- 7.2.2. Ship Industry

- 7.2.3. Machine Made

- 7.2.4. Others

- 7.2.5. World Copper Centrifugal Casting Production

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Europe Copper Centrifugal Casting Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Die Casting

- 8.1.2. Melting and Casting

- 8.1.3. World Copper Centrifugal Casting Production

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Automobile Industry

- 8.2.2. Ship Industry

- 8.2.3. Machine Made

- 8.2.4. Others

- 8.2.5. World Copper Centrifugal Casting Production

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Middle East & Africa Copper Centrifugal Casting Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Die Casting

- 9.1.2. Melting and Casting

- 9.1.3. World Copper Centrifugal Casting Production

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Automobile Industry

- 9.2.2. Ship Industry

- 9.2.3. Machine Made

- 9.2.4. Others

- 9.2.5. World Copper Centrifugal Casting Production

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Asia Pacific Copper Centrifugal Casting Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Type

- 10.1.1. Die Casting

- 10.1.2. Melting and Casting

- 10.1.3. World Copper Centrifugal Casting Production

- 10.2. Market Analysis, Insights and Forecast - by Application

- 10.2.1. Automobile Industry

- 10.2.2. Ship Industry

- 10.2.3. Machine Made

- 10.2.4. Others

- 10.2.5. World Copper Centrifugal Casting Production

- 10.1. Market Analysis, Insights and Forecast - by Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 Tallman Technologies

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Electric Materials

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 Conex Casting

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Anchor Bronze & Metals

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Conex Metals

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Kigema

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Johnson Centrifugal Technology

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Delta Centrifugal

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 NISARG CASTING

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Vaishnavi Metal Products

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Les Bronzes d'Industrie (LBI)

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Wisconsin Centrifugal Division

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 Bunty LLC

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 Bronze Foundry & Machine

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.1 Tallman Technologies

- Figure 1: Global Copper Centrifugal Casting Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: Global Copper Centrifugal Casting Volume Breakdown (K, %) by Region 2024 & 2032

- Figure 3: North America Copper Centrifugal Casting Revenue (million), by Type 2024 & 2032

- Figure 4: North America Copper Centrifugal Casting Volume (K), by Type 2024 & 2032

- Figure 5: North America Copper Centrifugal Casting Revenue Share (%), by Type 2024 & 2032

- Figure 6: North America Copper Centrifugal Casting Volume Share (%), by Type 2024 & 2032

- Figure 7: North America Copper Centrifugal Casting Revenue (million), by Application 2024 & 2032

- Figure 8: North America Copper Centrifugal Casting Volume (K), by Application 2024 & 2032

- Figure 9: North America Copper Centrifugal Casting Revenue Share (%), by Application 2024 & 2032

- Figure 10: North America Copper Centrifugal Casting Volume Share (%), by Application 2024 & 2032

- Figure 11: North America Copper Centrifugal Casting Revenue (million), by Country 2024 & 2032

- Figure 12: North America Copper Centrifugal Casting Volume (K), by Country 2024 & 2032

- Figure 13: North America Copper Centrifugal Casting Revenue Share (%), by Country 2024 & 2032

- Figure 14: North America Copper Centrifugal Casting Volume Share (%), by Country 2024 & 2032

- Figure 15: South America Copper Centrifugal Casting Revenue (million), by Type 2024 & 2032

- Figure 16: South America Copper Centrifugal Casting Volume (K), by Type 2024 & 2032

- Figure 17: South America Copper Centrifugal Casting Revenue Share (%), by Type 2024 & 2032

- Figure 18: South America Copper Centrifugal Casting Volume Share (%), by Type 2024 & 2032

- Figure 19: South America Copper Centrifugal Casting Revenue (million), by Application 2024 & 2032

- Figure 20: South America Copper Centrifugal Casting Volume (K), by Application 2024 & 2032

- Figure 21: South America Copper Centrifugal Casting Revenue Share (%), by Application 2024 & 2032

- Figure 22: South America Copper Centrifugal Casting Volume Share (%), by Application 2024 & 2032

- Figure 23: South America Copper Centrifugal Casting Revenue (million), by Country 2024 & 2032

- Figure 24: South America Copper Centrifugal Casting Volume (K), by Country 2024 & 2032

- Figure 25: South America Copper Centrifugal Casting Revenue Share (%), by Country 2024 & 2032

- Figure 26: South America Copper Centrifugal Casting Volume Share (%), by Country 2024 & 2032

- Figure 27: Europe Copper Centrifugal Casting Revenue (million), by Type 2024 & 2032

- Figure 28: Europe Copper Centrifugal Casting Volume (K), by Type 2024 & 2032

- Figure 29: Europe Copper Centrifugal Casting Revenue Share (%), by Type 2024 & 2032

- Figure 30: Europe Copper Centrifugal Casting Volume Share (%), by Type 2024 & 2032

- Figure 31: Europe Copper Centrifugal Casting Revenue (million), by Application 2024 & 2032

- Figure 32: Europe Copper Centrifugal Casting Volume (K), by Application 2024 & 2032

- Figure 33: Europe Copper Centrifugal Casting Revenue Share (%), by Application 2024 & 2032

- Figure 34: Europe Copper Centrifugal Casting Volume Share (%), by Application 2024 & 2032

- Figure 35: Europe Copper Centrifugal Casting Revenue (million), by Country 2024 & 2032

- Figure 36: Europe Copper Centrifugal Casting Volume (K), by Country 2024 & 2032

- Figure 37: Europe Copper Centrifugal Casting Revenue Share (%), by Country 2024 & 2032

- Figure 38: Europe Copper Centrifugal Casting Volume Share (%), by Country 2024 & 2032

- Figure 39: Middle East & Africa Copper Centrifugal Casting Revenue (million), by Type 2024 & 2032

- Figure 40: Middle East & Africa Copper Centrifugal Casting Volume (K), by Type 2024 & 2032

- Figure 41: Middle East & Africa Copper Centrifugal Casting Revenue Share (%), by Type 2024 & 2032

- Figure 42: Middle East & Africa Copper Centrifugal Casting Volume Share (%), by Type 2024 & 2032

- Figure 43: Middle East & Africa Copper Centrifugal Casting Revenue (million), by Application 2024 & 2032

- Figure 44: Middle East & Africa Copper Centrifugal Casting Volume (K), by Application 2024 & 2032

- Figure 45: Middle East & Africa Copper Centrifugal Casting Revenue Share (%), by Application 2024 & 2032

- Figure 46: Middle East & Africa Copper Centrifugal Casting Volume Share (%), by Application 2024 & 2032

- Figure 47: Middle East & Africa Copper Centrifugal Casting Revenue (million), by Country 2024 & 2032

- Figure 48: Middle East & Africa Copper Centrifugal Casting Volume (K), by Country 2024 & 2032

- Figure 49: Middle East & Africa Copper Centrifugal Casting Revenue Share (%), by Country 2024 & 2032

- Figure 50: Middle East & Africa Copper Centrifugal Casting Volume Share (%), by Country 2024 & 2032

- Figure 51: Asia Pacific Copper Centrifugal Casting Revenue (million), by Type 2024 & 2032

- Figure 52: Asia Pacific Copper Centrifugal Casting Volume (K), by Type 2024 & 2032

- Figure 53: Asia Pacific Copper Centrifugal Casting Revenue Share (%), by Type 2024 & 2032

- Figure 54: Asia Pacific Copper Centrifugal Casting Volume Share (%), by Type 2024 & 2032

- Figure 55: Asia Pacific Copper Centrifugal Casting Revenue (million), by Application 2024 & 2032

- Figure 56: Asia Pacific Copper Centrifugal Casting Volume (K), by Application 2024 & 2032

- Figure 57: Asia Pacific Copper Centrifugal Casting Revenue Share (%), by Application 2024 & 2032

- Figure 58: Asia Pacific Copper Centrifugal Casting Volume Share (%), by Application 2024 & 2032

- Figure 59: Asia Pacific Copper Centrifugal Casting Revenue (million), by Country 2024 & 2032

- Figure 60: Asia Pacific Copper Centrifugal Casting Volume (K), by Country 2024 & 2032

- Figure 61: Asia Pacific Copper Centrifugal Casting Revenue Share (%), by Country 2024 & 2032

- Figure 62: Asia Pacific Copper Centrifugal Casting Volume Share (%), by Country 2024 & 2032

- Table 1: Global Copper Centrifugal Casting Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Copper Centrifugal Casting Volume K Forecast, by Region 2019 & 2032

- Table 3: Global Copper Centrifugal Casting Revenue million Forecast, by Type 2019 & 2032

- Table 4: Global Copper Centrifugal Casting Volume K Forecast, by Type 2019 & 2032

- Table 5: Global Copper Centrifugal Casting Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global Copper Centrifugal Casting Volume K Forecast, by Application 2019 & 2032

- Table 7: Global Copper Centrifugal Casting Revenue million Forecast, by Region 2019 & 2032

- Table 8: Global Copper Centrifugal Casting Volume K Forecast, by Region 2019 & 2032

- Table 9: Global Copper Centrifugal Casting Revenue million Forecast, by Type 2019 & 2032

- Table 10: Global Copper Centrifugal Casting Volume K Forecast, by Type 2019 & 2032

- Table 11: Global Copper Centrifugal Casting Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global Copper Centrifugal Casting Volume K Forecast, by Application 2019 & 2032

- Table 13: Global Copper Centrifugal Casting Revenue million Forecast, by Country 2019 & 2032

- Table 14: Global Copper Centrifugal Casting Volume K Forecast, by Country 2019 & 2032

- Table 15: United States Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: United States Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 17: Canada Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 18: Canada Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 19: Mexico Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 20: Mexico Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 21: Global Copper Centrifugal Casting Revenue million Forecast, by Type 2019 & 2032

- Table 22: Global Copper Centrifugal Casting Volume K Forecast, by Type 2019 & 2032

- Table 23: Global Copper Centrifugal Casting Revenue million Forecast, by Application 2019 & 2032

- Table 24: Global Copper Centrifugal Casting Volume K Forecast, by Application 2019 & 2032

- Table 25: Global Copper Centrifugal Casting Revenue million Forecast, by Country 2019 & 2032

- Table 26: Global Copper Centrifugal Casting Volume K Forecast, by Country 2019 & 2032

- Table 27: Brazil Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Brazil Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 29: Argentina Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 30: Argentina Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 31: Rest of South America Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 32: Rest of South America Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 33: Global Copper Centrifugal Casting Revenue million Forecast, by Type 2019 & 2032

- Table 34: Global Copper Centrifugal Casting Volume K Forecast, by Type 2019 & 2032

- Table 35: Global Copper Centrifugal Casting Revenue million Forecast, by Application 2019 & 2032

- Table 36: Global Copper Centrifugal Casting Volume K Forecast, by Application 2019 & 2032

- Table 37: Global Copper Centrifugal Casting Revenue million Forecast, by Country 2019 & 2032

- Table 38: Global Copper Centrifugal Casting Volume K Forecast, by Country 2019 & 2032

- Table 39: United Kingdom Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 40: United Kingdom Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 41: Germany Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: Germany Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 43: France Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: France Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 45: Italy Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Italy Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 47: Spain Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 48: Spain Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 49: Russia Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 50: Russia Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 51: Benelux Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 52: Benelux Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 53: Nordics Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 54: Nordics Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 55: Rest of Europe Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 56: Rest of Europe Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 57: Global Copper Centrifugal Casting Revenue million Forecast, by Type 2019 & 2032

- Table 58: Global Copper Centrifugal Casting Volume K Forecast, by Type 2019 & 2032

- Table 59: Global Copper Centrifugal Casting Revenue million Forecast, by Application 2019 & 2032

- Table 60: Global Copper Centrifugal Casting Volume K Forecast, by Application 2019 & 2032

- Table 61: Global Copper Centrifugal Casting Revenue million Forecast, by Country 2019 & 2032

- Table 62: Global Copper Centrifugal Casting Volume K Forecast, by Country 2019 & 2032

- Table 63: Turkey Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 64: Turkey Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 65: Israel Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 66: Israel Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 67: GCC Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 68: GCC Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 69: North Africa Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 70: North Africa Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 71: South Africa Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 72: South Africa Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 73: Rest of Middle East & Africa Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 74: Rest of Middle East & Africa Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 75: Global Copper Centrifugal Casting Revenue million Forecast, by Type 2019 & 2032

- Table 76: Global Copper Centrifugal Casting Volume K Forecast, by Type 2019 & 2032

- Table 77: Global Copper Centrifugal Casting Revenue million Forecast, by Application 2019 & 2032

- Table 78: Global Copper Centrifugal Casting Volume K Forecast, by Application 2019 & 2032

- Table 79: Global Copper Centrifugal Casting Revenue million Forecast, by Country 2019 & 2032

- Table 80: Global Copper Centrifugal Casting Volume K Forecast, by Country 2019 & 2032

- Table 81: China Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 82: China Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 83: India Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 84: India Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 85: Japan Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 86: Japan Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 87: South Korea Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 88: South Korea Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 89: ASEAN Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 90: ASEAN Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 91: Oceania Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 92: Oceania Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

- Table 93: Rest of Asia Pacific Copper Centrifugal Casting Revenue (million) Forecast, by Application 2019 & 2032

- Table 94: Rest of Asia Pacific Copper Centrifugal Casting Volume (K) Forecast, by Application 2019 & 2032

STEP 1 - Identification of Relevant Samples Size from Population Database

STEP 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note* : In applicable scenarios

STEP 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

STEP 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

Frequently Asked Questions

Related Reports

About Market Research Forecast

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.