Plant Relocation Service

Plant Relocation ServicePlant Relocation Service Analysis Report 2025: Market to Grow by a CAGR of XX to 2033, Driven by Government Incentives, Popularity of Virtual Assistants, and Strategic Partnerships

Plant Relocation Service by Application (Machining, Textile Industry, Food Industry, Electronics, Other), by Type (International Factory Relocation, Domestic Factory Relocation), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

Base Year: 2024

151 Pages

Key Insights

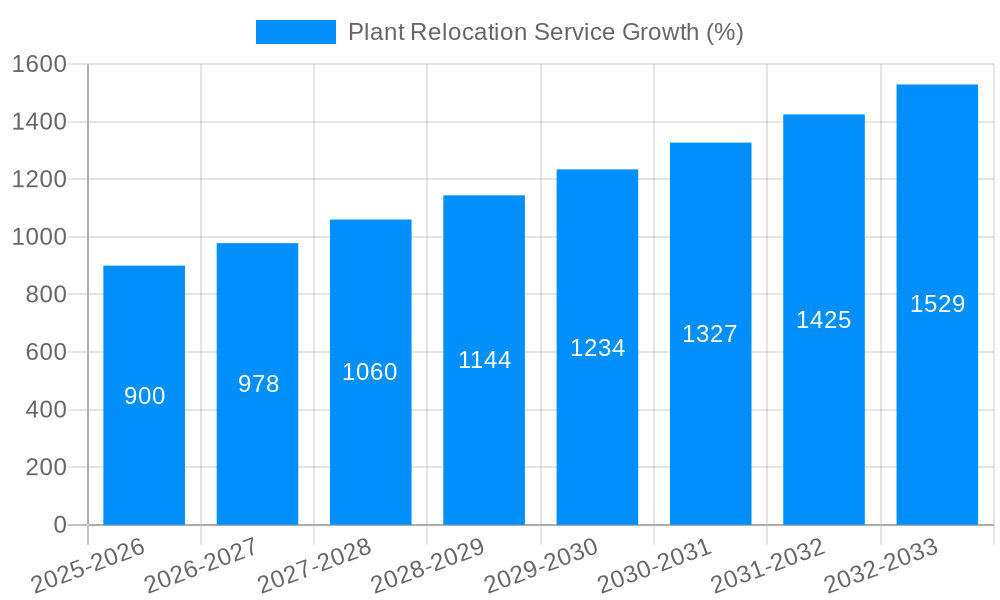

The global plant relocation services market is experiencing robust growth, driven by several key factors. Increased globalization and the pursuit of lower operational costs are prompting businesses across various sectors, including manufacturing (machining, textile, food, electronics), to relocate their facilities domestically or internationally. This trend is further fueled by the need for improved infrastructure, access to skilled labor, proximity to key markets, and government incentives offered in specific regions. The market is segmented by application (machining, textile, food, electronics, and other) and type of relocation (international vs. domestic). While precise market sizing data is unavailable, considering the substantial investment involved in plant relocations and the growing prevalence of global supply chain restructuring, a reasonable estimation of the 2025 market size could be around $15 billion. This figure is supported by the involvement of numerous large and specialized companies offering a diverse range of relocation services, from machinery moving and rigging to project management and logistical support. The market's Compound Annual Growth Rate (CAGR) is anticipated to be in the range of 6-8% from 2025-2033, reflecting sustained demand for these services as businesses actively adapt to evolving economic and market conditions. This sustained growth will likely be driven by ongoing expansion in developing economies and advancements in relocation technologies, facilitating smoother and more cost-effective operations.

However, the market faces certain restraints. These include the high upfront costs associated with plant relocations, regulatory hurdles and compliance requirements that vary significantly between regions, and disruptions to ongoing production during the relocation process. Geopolitical uncertainties and supply chain vulnerabilities also pose challenges. Despite these factors, the long-term growth outlook remains positive. The market is likely to witness increased consolidation as larger firms acquire smaller specialized players to expand their service offerings and geographical reach. Technological innovation, including automation and digitalization of logistics processes, will play a crucial role in optimizing efficiency and reducing costs. This, in turn, will enhance the competitiveness of the industry and sustain the growth trajectory for the foreseeable future.

Plant Relocation Service Trends

The global plant relocation service market is experiencing robust growth, projected to reach USD XXX million by 2033, exhibiting a CAGR of X% during the forecast period (2025-2033). This expansion is fueled by several converging factors, primarily the ongoing shift in global manufacturing landscapes, the increasing need for businesses to optimize operational efficiency and reduce costs, and a rising demand for specialized expertise in handling complex industrial relocation projects. The historical period (2019-2024) witnessed a steady increase in market size, laying the foundation for the accelerated growth anticipated in the coming years. The base year 2025 serves as a crucial benchmark, reflecting the culmination of past trends and the launchpad for future expansion. Market analysis reveals a clear preference for specialized services, with companies increasingly outsourcing complete relocation management rather than handling individual aspects in-house. This trend highlights the increasing complexity of modern manufacturing facilities and the associated risks involved in self-managed relocations. Furthermore, the growing adoption of advanced technologies like robotics and automation in plant relocation projects further contributes to the market's expansion. The estimated year 2025 figures suggest a significant market maturity, paving the way for continued growth driven by technological advancements and evolving business strategies. Key market insights indicate a strong correlation between economic growth in key regions and the demand for plant relocation services, with emerging economies playing an increasingly significant role in the market's expansion.

Driving Forces: What's Propelling the Plant Relocation Service

Several key factors are propelling the growth of the plant relocation service market. Firstly, the ongoing globalization of manufacturing necessitates the relocation of plants to optimize supply chains, access new markets, and reduce production costs. This is particularly evident in industries like electronics and textiles, where manufacturing hubs are constantly shifting. Secondly, the need for enhanced operational efficiency is a major driver. Companies are increasingly seeking ways to streamline their production processes and reduce downtime during relocation, leading them to engage specialized service providers. Thirdly, the complexities of modern manufacturing facilities demand expertise in dismantling, transporting, and reassembling intricate equipment. This necessitates specialized skills and advanced technologies only available through professional relocation services. Finally, the growing awareness of the risks associated with self-managed relocation projects is driving companies toward outsourcing this critical function to experienced professionals, mitigating potential disruptions and financial losses. This trend is further exacerbated by stringent safety regulations and environmental concerns, which require specialized handling and disposal procedures.

Challenges and Restraints in Plant Relocation Service

Despite the significant growth potential, the plant relocation service market faces several challenges. High upfront costs associated with hiring specialized contractors and managing complex logistics represent a major barrier for smaller businesses. Furthermore, geopolitical uncertainties and trade regulations can disrupt cross-border relocation projects, increasing complexities and costs. Finding and retaining skilled labor is another significant challenge, with the industry facing a shortage of professionals with the requisite expertise in handling specialized equipment and technologies. Regulatory hurdles and compliance requirements related to environmental protection and worker safety further complicate relocation processes, especially in international projects. Finally, coordinating the relocation of intricate manufacturing processes, ensuring minimal disruption to production, and minimizing downtime remain significant hurdles that require meticulous planning and execution. The competitive landscape, characterized by a mix of large multinational companies and smaller specialized firms, can also pose challenges in terms of price competition and securing contracts.

Key Region or Country & Segment to Dominate the Market

The Domestic Factory Relocation segment is projected to dominate the market, driven by the significant cost savings and reduced logistical complexities compared to international relocation. This trend is particularly apparent in developed economies with established manufacturing bases.

North America: The region is expected to be a significant market due to its large manufacturing base and the presence of numerous established relocation service providers. The high concentration of advanced manufacturing industries and a robust economy contribute significantly to the demand.

Europe: The European market is driven by a mix of factors including regional economic activity, the reshoring of some manufacturing activities, and the need for businesses to adapt to changing market conditions. Regulations related to environmental standards and worker safety play a significant role in shaping the market.

Asia-Pacific: While primarily driven by international relocation in the past, the domestic factory relocation market is gaining momentum due to the increasing manufacturing capacity and the expanding presence of multinational corporations within the region.

Machining Application: This application segment is projected to witness robust growth fueled by the increasing demand for precision-engineered components and the need for efficient manufacturing processes. Relocation of machining facilities necessitates specialized equipment handling and expertise, further driving the market.

The Food Industry segment also displays significant potential for growth due to the stringent hygiene and safety regulations surrounding food production. Specialized relocation services are crucial to ensure compliance and minimize disruption.

Growth Catalysts in Plant Relocation Service Industry

Several factors are catalyzing growth within the plant relocation service industry. These include increasing automation in the relocation process, resulting in greater efficiency and reduced downtime; the growing adoption of advanced project management software enhancing planning and execution; and the increasing emphasis on sustainability, leading to more environmentally conscious relocation practices. These combined factors contribute to a more efficient, streamlined, and cost-effective plant relocation process, significantly boosting market growth.

Leading Players in the Plant Relocation Service

- Cherokee Millwright

- Beck & Pollitzer

- SGS

- AssureShift

- Meyer Rigging

- A&A Machinery Moving

- CSM Group, Inc.

- Deufol SE

- Gottstein Corporation

- Red Carpet Movers

- Modpack

- Balsons Heavy Lift & Shift

- AIS EURELO

- Machinery Movers & Erectors

- AIM Industrial

- Linde

- Pro-Per Energy Services

- Canton Erectors

- EMCOR Group, Inc

- Blue Projects

- Guy M. Turner

Significant Developments in Plant Relocation Service Sector

- 2020: Increased adoption of virtual reality and augmented reality technologies for planning and execution of complex relocation projects.

- 2021: Several major players invested heavily in developing specialized equipment and transportation solutions for sensitive manufacturing equipment.

- 2022: A surge in demand for sustainable and environmentally friendly relocation practices, including waste reduction and carbon footprint minimization.

- 2023: Several partnerships were formed between relocation service providers and technology companies to enhance efficiency and automation.

Comprehensive Coverage Plant Relocation Service Report

This report provides a comprehensive analysis of the plant relocation service market, offering invaluable insights into market trends, growth drivers, challenges, and key players. The detailed segmentation by application and relocation type, along with regional breakdowns, provides a granular understanding of the market dynamics. The inclusion of historical data, base year estimates, and future forecasts empowers businesses to make informed strategic decisions. The report's emphasis on key market trends and growth catalysts underscores the significant opportunities within this rapidly evolving sector.

Plant Relocation Service Segmentation

-

1. Application

- 1.1. Machining

- 1.2. Textile Industry

- 1.3. Food Industry

- 1.4. Electronics

- 1.5. Other

-

2. Type

- 2.1. International Factory Relocation

- 2.2. Domestic Factory Relocation

Plant Relocation Service Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Plant Relocation Service REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

Frequently Asked Questions

Table Of Content

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Plant Relocation Service Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Application

- 5.1.1. Machining

- 5.1.2. Textile Industry

- 5.1.3. Food Industry

- 5.1.4. Electronics

- 5.1.5. Other

- 5.2. Market Analysis, Insights and Forecast - by Type

- 5.2.1. International Factory Relocation

- 5.2.2. Domestic Factory Relocation

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Application

- 6. North America Plant Relocation Service Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Application

- 6.1.1. Machining

- 6.1.2. Textile Industry

- 6.1.3. Food Industry

- 6.1.4. Electronics

- 6.1.5. Other

- 6.2. Market Analysis, Insights and Forecast - by Type

- 6.2.1. International Factory Relocation

- 6.2.2. Domestic Factory Relocation

- 6.1. Market Analysis, Insights and Forecast - by Application

- 7. South America Plant Relocation Service Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Application

- 7.1.1. Machining

- 7.1.2. Textile Industry

- 7.1.3. Food Industry

- 7.1.4. Electronics

- 7.1.5. Other

- 7.2. Market Analysis, Insights and Forecast - by Type

- 7.2.1. International Factory Relocation

- 7.2.2. Domestic Factory Relocation

- 7.1. Market Analysis, Insights and Forecast - by Application

- 8. Europe Plant Relocation Service Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Application

- 8.1.1. Machining

- 8.1.2. Textile Industry

- 8.1.3. Food Industry

- 8.1.4. Electronics

- 8.1.5. Other

- 8.2. Market Analysis, Insights and Forecast - by Type

- 8.2.1. International Factory Relocation

- 8.2.2. Domestic Factory Relocation

- 8.1. Market Analysis, Insights and Forecast - by Application

- 9. Middle East & Africa Plant Relocation Service Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Application

- 9.1.1. Machining

- 9.1.2. Textile Industry

- 9.1.3. Food Industry

- 9.1.4. Electronics

- 9.1.5. Other

- 9.2. Market Analysis, Insights and Forecast - by Type

- 9.2.1. International Factory Relocation

- 9.2.2. Domestic Factory Relocation

- 9.1. Market Analysis, Insights and Forecast - by Application

- 10. Asia Pacific Plant Relocation Service Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Application

- 10.1.1. Machining

- 10.1.2. Textile Industry

- 10.1.3. Food Industry

- 10.1.4. Electronics

- 10.1.5. Other

- 10.2. Market Analysis, Insights and Forecast - by Type

- 10.2.1. International Factory Relocation

- 10.2.2. Domestic Factory Relocation

- 10.1. Market Analysis, Insights and Forecast - by Application

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 Cherokee Millwright

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Beck & Pollitzer

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 SGS

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 AssureShift

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Meyer Rigging

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 A&A Machinery Moving

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 CSM Group Inc.

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 Deufol SE

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Gottstein Corporation

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Red Carpet Movers

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Modpack

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Balsons Heavy Lift & Shift

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 AIS EURELO

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 Machinery Movers & Erectors

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.15 AIM Industrial

- 11.2.15.1. Overview

- 11.2.15.2. Products

- 11.2.15.3. SWOT Analysis

- 11.2.15.4. Recent Developments

- 11.2.15.5. Financials (Based on Availability)

- 11.2.16 Linde

- 11.2.16.1. Overview

- 11.2.16.2. Products

- 11.2.16.3. SWOT Analysis

- 11.2.16.4. Recent Developments

- 11.2.16.5. Financials (Based on Availability)

- 11.2.17 Pro-Per Energy Services

- 11.2.17.1. Overview

- 11.2.17.2. Products

- 11.2.17.3. SWOT Analysis

- 11.2.17.4. Recent Developments

- 11.2.17.5. Financials (Based on Availability)

- 11.2.18 Canton Erectors

- 11.2.18.1. Overview

- 11.2.18.2. Products

- 11.2.18.3. SWOT Analysis

- 11.2.18.4. Recent Developments

- 11.2.18.5. Financials (Based on Availability)

- 11.2.19 EMCOR Group Inc

- 11.2.19.1. Overview

- 11.2.19.2. Products

- 11.2.19.3. SWOT Analysis

- 11.2.19.4. Recent Developments

- 11.2.19.5. Financials (Based on Availability)

- 11.2.20 Blue Projects

- 11.2.20.1. Overview

- 11.2.20.2. Products

- 11.2.20.3. SWOT Analysis

- 11.2.20.4. Recent Developments

- 11.2.20.5. Financials (Based on Availability)

- 11.2.21 Guy M. Turner

- 11.2.21.1. Overview

- 11.2.21.2. Products

- 11.2.21.3. SWOT Analysis

- 11.2.21.4. Recent Developments

- 11.2.21.5. Financials (Based on Availability)

- 11.2.22

- 11.2.22.1. Overview

- 11.2.22.2. Products

- 11.2.22.3. SWOT Analysis

- 11.2.22.4. Recent Developments

- 11.2.22.5. Financials (Based on Availability)

- 11.2.1 Cherokee Millwright

List of Figures

- Figure 1: Global Plant Relocation Service Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Plant Relocation Service Revenue (million), by Application 2024 & 2032

- Figure 3: North America Plant Relocation Service Revenue Share (%), by Application 2024 & 2032

- Figure 4: North America Plant Relocation Service Revenue (million), by Type 2024 & 2032

- Figure 5: North America Plant Relocation Service Revenue Share (%), by Type 2024 & 2032

- Figure 6: North America Plant Relocation Service Revenue (million), by Country 2024 & 2032

- Figure 7: North America Plant Relocation Service Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Plant Relocation Service Revenue (million), by Application 2024 & 2032

- Figure 9: South America Plant Relocation Service Revenue Share (%), by Application 2024 & 2032

- Figure 10: South America Plant Relocation Service Revenue (million), by Type 2024 & 2032

- Figure 11: South America Plant Relocation Service Revenue Share (%), by Type 2024 & 2032

- Figure 12: South America Plant Relocation Service Revenue (million), by Country 2024 & 2032

- Figure 13: South America Plant Relocation Service Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Plant Relocation Service Revenue (million), by Application 2024 & 2032

- Figure 15: Europe Plant Relocation Service Revenue Share (%), by Application 2024 & 2032

- Figure 16: Europe Plant Relocation Service Revenue (million), by Type 2024 & 2032

- Figure 17: Europe Plant Relocation Service Revenue Share (%), by Type 2024 & 2032

- Figure 18: Europe Plant Relocation Service Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Plant Relocation Service Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Plant Relocation Service Revenue (million), by Application 2024 & 2032

- Figure 21: Middle East & Africa Plant Relocation Service Revenue Share (%), by Application 2024 & 2032

- Figure 22: Middle East & Africa Plant Relocation Service Revenue (million), by Type 2024 & 2032

- Figure 23: Middle East & Africa Plant Relocation Service Revenue Share (%), by Type 2024 & 2032

- Figure 24: Middle East & Africa Plant Relocation Service Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Plant Relocation Service Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Plant Relocation Service Revenue (million), by Application 2024 & 2032

- Figure 27: Asia Pacific Plant Relocation Service Revenue Share (%), by Application 2024 & 2032

- Figure 28: Asia Pacific Plant Relocation Service Revenue (million), by Type 2024 & 2032

- Figure 29: Asia Pacific Plant Relocation Service Revenue Share (%), by Type 2024 & 2032

- Figure 30: Asia Pacific Plant Relocation Service Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Plant Relocation Service Revenue Share (%), by Country 2024 & 2032

List of Tables

- Table 1: Global Plant Relocation Service Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Plant Relocation Service Revenue million Forecast, by Application 2019 & 2032

- Table 3: Global Plant Relocation Service Revenue million Forecast, by Type 2019 & 2032

- Table 4: Global Plant Relocation Service Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Plant Relocation Service Revenue million Forecast, by Application 2019 & 2032

- Table 6: Global Plant Relocation Service Revenue million Forecast, by Type 2019 & 2032

- Table 7: Global Plant Relocation Service Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Plant Relocation Service Revenue million Forecast, by Application 2019 & 2032

- Table 12: Global Plant Relocation Service Revenue million Forecast, by Type 2019 & 2032

- Table 13: Global Plant Relocation Service Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Plant Relocation Service Revenue million Forecast, by Application 2019 & 2032

- Table 18: Global Plant Relocation Service Revenue million Forecast, by Type 2019 & 2032

- Table 19: Global Plant Relocation Service Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Plant Relocation Service Revenue million Forecast, by Application 2019 & 2032

- Table 30: Global Plant Relocation Service Revenue million Forecast, by Type 2019 & 2032

- Table 31: Global Plant Relocation Service Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Plant Relocation Service Revenue million Forecast, by Application 2019 & 2032

- Table 39: Global Plant Relocation Service Revenue million Forecast, by Type 2019 & 2032

- Table 40: Global Plant Relocation Service Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Plant Relocation Service Revenue (million) Forecast, by Application 2019 & 2032

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of XX% from 2019-2033 |

| Segmentation |

|

STEP 1 - Identification of Relevant Samples Size from Population Database

STEP 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Top-down and bottom-up approaches are used to validate the global market size and estimate the market size for manufactures, regional segemnts, product and application.

Note* : In applicable scenarios

STEP 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

STEP 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

Additionally after gathering mix and scattered data from wide range of sources, data is triangull- ated and correlated to come up with estimated figures which are further validated through primary mediums, or industry experts, opinion leader.

About Market Research Forecast

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.