Sputtering Coating Pure Metal Material

Sputtering Coating Pure Metal MaterialSputtering Coating Pure Metal Material Unlocking Growth Potential: Analysis and Forecasts 2025-2033

Sputtering Coating Pure Metal Material by Type (Aluminum, Titanium, Tantalum, Copper, Others), by Application (Semiconductor, Flat Panel Display Panel, Thin Film Solar Cell, Storage Media), by North America (United States, Canada, Mexico), by South America (Brazil, Argentina, Rest of South America), by Europe (United Kingdom, Germany, France, Italy, Spain, Russia, Benelux, Nordics, Rest of Europe), by Middle East & Africa (Turkey, Israel, GCC, North Africa, South Africa, Rest of Middle East & Africa), by Asia Pacific (China, India, Japan, South Korea, ASEAN, Oceania, Rest of Asia Pacific) Forecast 2025-2033

Key Insights

The global sputtering coating pure metal material market is projected to reach $4472 million by 2033, growing at a CAGR of 8.8% from 2025 to 2033. The growth of the market is attributed to the increasing demand for sputtering coating pure metal materials in the semiconductor, flat panel display panel, thin film solar cell, and storage media industries. These materials are used to improve the electrical, optical, and mechanical properties of various substrates.

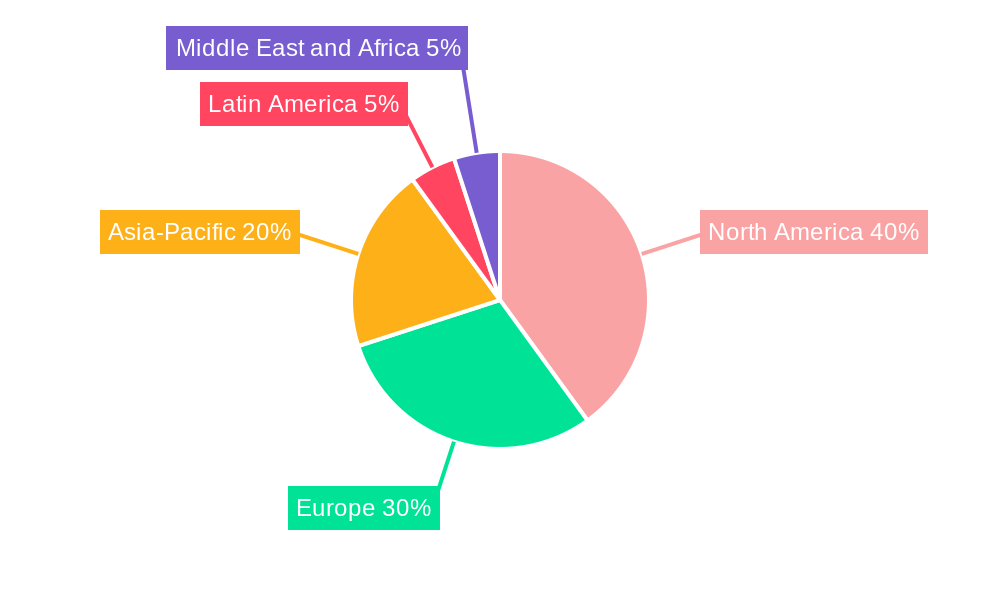

Major trends driving the growth of the sputtering coating pure metal material market include the increasing adoption of advanced electronic devices, the growing demand for flexible electronics, and the development of new and improved sputtering techniques. However, the market is restrained by factors such as the high cost of sputtering equipment and the complex manufacturing process. The market is segmented by type, application, and region. Among the different types of sputtering coating pure metal materials, aluminum is the most widely used, followed by titanium, tantalum, copper, and others. In terms of application, the semiconductor industry is the largest consumer of sputtering coating pure metal materials, followed by the flat panel display panel, thin film solar cell, and storage media industries. Regionally, Asia Pacific is the largest market for sputtering coating pure metal materials, followed by North America and Europe.

Sputtering Coating Pure Metal Material Trends

The global sputtering coating pure metal material market is projected to grow from XXX million in 2023 to XXX million by 2030, at a CAGR of XX%. The increasing demand for pure metals in the semiconductor and electronics industries is driving the growth of the market.

Pure metals are used in a variety of applications, including:

- Semiconductors: Pure metals are used as electrodes and interconnects in semiconductor devices.

- Electronics: Pure metals are used in printed circuit boards (PCBs), connectors, and other electronic components.

- Optics: Pure metals are used in reflective and anti-reflective coatings.

- Medical: Pure metals are used in medical implants and devices.

The sputtering coating process is a thin-film deposition technique that uses a plasma to sputter atoms from a target material onto a substrate. This process can be used to deposit a wide variety of materials, including pure metals.

Driving Forces: What's Propelling the Sputtering Coating Pure Metal Material

Several factors are driving the growth of the sputtering coating pure metal material market:

- Increasing demand for semiconductors: The demand for semiconductors is growing rapidly, driven by the growth of the electronics industry. This growth is expected to continue in the coming years, as the demand for electronic devices such as smartphones, tablets, and laptops continues to increase.

- Growing use of pure metals in electronics: Pure metals are increasingly being used in electronics due to their superior electrical and thermal conductivity. This trend is expected to continue as the electronics industry continues to develop new and innovative products.

- Government support for the semiconductor industry: Governments around the world are providing support for the semiconductor industry in order to boost economic growth. This support is expected to continue in the coming years, as the semiconductor industry becomes increasingly important to the global economy.

Challenges and Restraints in Sputtering Coating Pure Metal Material

Despite the strong growth potential, the sputtering coating pure metal material market faces several challenges:

- High cost of pure metals: Pure metals are expensive to produce, which can limit their use in some applications.

- Technical challenges: The sputtering coating process is a complex and technical process that requires specialized equipment and expertise.

- Competition from other thin-film deposition techniques: Other thin-film deposition techniques, such as chemical vapor deposition (CVD) and physical vapor deposition (PVD), can be used to deposit pure metals. These techniques are often less expensive than sputtering, which can limit the market for sputtering coated pure metals.

Key Region or Country & Segment to Dominate the Market

The Asia-Pacific region is expected to dominate the sputtering coating pure metal material market over the forecast period. The region is home to a large number of semiconductor manufacturers, which are driving the demand for pure metals. China is the largest market for sputtering coated pure metals in the Asia-Pacific region, and this trend is expected to continue in the coming years.

The semiconductor segment is expected to be the largest segment of the sputtering coating pure metal material market over the forecast period. The growth of this segment is being driven by the increasing demand for semiconductors in the electronics industry. The flat panel display segment is also expected to experience significant growth over the forecast period, due to the growing demand for flat panel displays in TVs, monitors, and other electronic devices.

Growth Catalysts in Sputtering Coating Pure Metal Material Industry

Several factors are expected to catalyze the growth of the sputtering coating pure metal material industry in the coming years:

- Increasing investment in the semiconductor industry: Governments and companies around the world are investing heavily in the semiconductor industry. This investment is expected to continue in the coming years, as the semiconductor industry becomes increasingly important to the global economy.

- Development of new applications for pure metals: Pure metals are being used in a growing number of applications, including in the medical, automotive, and aerospace industries. This trend is expected to continue in the coming years, as new applications for pure metals are developed.

- Government regulations: Governments around the world are implementing regulations to reduce the environmental impact of the electronics industry. These regulations are expected to drive the demand for pure metals, as they are more environmentally friendly than other materials.

Leading Players in the Sputtering Coating Pure Metal Material

The leading players in the sputtering coating pure metal material market [link rel="nofollow"]TANAKA HOLDINGS Co., Ltd[/link]], [link rel="nofollow"]Honeywell[/link]], [link rel="nofollow"]JX Advanced Metals Corporation[/link]], [link rel="nofollow"]Tosoh[/link]], [link rel="nofollow"]Praxair[/link]], [link rel="nofollow"]Solar Applied Materials Technology Corp[/link]], [link rel="nofollow"]Sumitomo Chemical[/link]], [link rel="nofollow"]H.C. Starck Tungsten Powders[/link]], [link rel="nofollow"]Materion[/link]], [link rel="nofollow"]Ulvac Materials[/link]], [link rel="nofollow"]Fujian Acetron New[/link]], [link rel="nofollow"]Konfoong Materials International Co Ltd[/link]], [link rel="nofollow"]Grinm Semiconductor Materials Co., Ltd[/link]], [link rel="nofollow"]LONGHUA TECHNOLOGY GROUP LUOYANG CO LTD[/link]].

These companies offer a wide range of sputtering coating pure metal materials, including aluminum, titanium, tantalum, copper, and others. They also offer a variety of sputtering coating services, including custom coating, batch coating, and roll-to-roll coating.

Significant Developments in Sputtering Coating Pure Metal Material Sector

Several significant developments have taken place in the sputtering coating pure metal material sector in recent years:

- Development of new target materials: New target materials have been developed that allow for the deposition of pure metals with improved properties. These new materials are expected to improve the performance and reliability of sputtering coated pure metals.

- Advancements in sputtering technology: Advancements in sputtering technology have led to the development of new sputtering systems that are more efficient and reliable. These new systems are expected to reduce the cost of sputtering coating pure metals.

- Integration of sputtering with other thin-film deposition techniques: Sputtering is increasingly being integrated with other thin-film deposition techniques, such as CVD and PVD. This integration is expected to enable the deposition of complex and multi-layer structures that are not possible with sputtering alone.

Comprehensive Coverage Sputtering Coating Pure Metal Material Report

This comprehensive report provides an in-depth analysis of the sputtering coating pure metal material market. The report covers the market size, trends, drivers, challenges, and restraints. The report also provides a detailed analysis of the key segments and regions of the market. The report is a valuable resource for anyone who is interested in the sputtering coating pure metal material market.

Sputtering Coating Pure Metal Material Segmentation

-

1. Type

- 1.1. Aluminum

- 1.2. Titanium

- 1.3. Tantalum

- 1.4. Copper

- 1.5. Others

-

2. Application

- 2.1. Semiconductor

- 2.2. Flat Panel Display Panel

- 2.3. Thin Film Solar Cell

- 2.4. Storage Media

Sputtering Coating Pure Metal Material Segmentation By Geography

-

1. North America

- 1.1. United States

- 1.2. Canada

- 1.3. Mexico

-

2. South America

- 2.1. Brazil

- 2.2. Argentina

- 2.3. Rest of South America

-

3. Europe

- 3.1. United Kingdom

- 3.2. Germany

- 3.3. France

- 3.4. Italy

- 3.5. Spain

- 3.6. Russia

- 3.7. Benelux

- 3.8. Nordics

- 3.9. Rest of Europe

-

4. Middle East & Africa

- 4.1. Turkey

- 4.2. Israel

- 4.3. GCC

- 4.4. North Africa

- 4.5. South Africa

- 4.6. Rest of Middle East & Africa

-

5. Asia Pacific

- 5.1. China

- 5.2. India

- 5.3. Japan

- 5.4. South Korea

- 5.5. ASEAN

- 5.6. Oceania

- 5.7. Rest of Asia Pacific

Sputtering Coating Pure Metal Material REPORT HIGHLIGHTS

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 8.8% from 2019-2033 |

| Segmentation |

|

Frequently Asked Questions

Can you provide details about the market size?

The market size is estimated to be USD 4472 million as of 2022.

How can I stay updated on further developments or reports in the Sputtering Coating Pure Metal Material?

To stay informed about further developments, trends, and reports in the Sputtering Coating Pure Metal Material, consider subscribing to industry newsletters, following relevant companies and organizations, or regularly checking reputable industry news sources and publications.

What is the projected Compound Annual Growth Rate (CAGR) of the Sputtering Coating Pure Metal Material ?

The projected CAGR is approximately 8.8%.

Is the market size provided in terms of value or volume?

The market size is provided in terms of value, measured in million .

Are there any restraints impacting market growth?

.

Which companies are prominent players in the Sputtering Coating Pure Metal Material?

Key companies in the market include TANAKA HOLDINGS Co., Ltd,Honeywell,JX Advanced Metals Corporation,Tosoh,Praxair,Solar Applied Materials Technology Corp,Sumitomo Chemical,H.C. Starck Tungsten Powders,Materion,Ulvac Materials,Fujian Acetron New,Konfoong Materials International Co Ltd,Grinm Semiconductor Materials Co., Ltd,LONGHUA TECHNOLOGY GROUP LUOYANG CO LTD

What are the main segments of the Sputtering Coating Pure Metal Material?

The market segments include

What are some drivers contributing to market growth?

.

- 1. Introduction

- 1.1. Research Scope

- 1.2. Market Segmentation

- 1.3. Research Methodology

- 1.4. Definitions and Assumptions

- 2. Executive Summary

- 2.1. Introduction

- 3. Market Dynamics

- 3.1. Introduction

- 3.2. Market Drivers

- 3.3. Market Restrains

- 3.4. Market Trends

- 4. Market Factor Analysis

- 4.1. Porters Five Forces

- 4.2. Supply/Value Chain

- 4.3. PESTEL analysis

- 4.4. Market Entropy

- 4.5. Patent/Trademark Analysis

- 5. Global Sputtering Coating Pure Metal Material Analysis, Insights and Forecast, 2019-2031

- 5.1. Market Analysis, Insights and Forecast - by Type

- 5.1.1. Aluminum

- 5.1.2. Titanium

- 5.1.3. Tantalum

- 5.1.4. Copper

- 5.1.5. Others

- 5.2. Market Analysis, Insights and Forecast - by Application

- 5.2.1. Semiconductor

- 5.2.2. Flat Panel Display Panel

- 5.2.3. Thin Film Solar Cell

- 5.2.4. Storage Media

- 5.3. Market Analysis, Insights and Forecast - by Region

- 5.3.1. North America

- 5.3.2. South America

- 5.3.3. Europe

- 5.3.4. Middle East & Africa

- 5.3.5. Asia Pacific

- 5.1. Market Analysis, Insights and Forecast - by Type

- 6. North America Sputtering Coating Pure Metal Material Analysis, Insights and Forecast, 2019-2031

- 6.1. Market Analysis, Insights and Forecast - by Type

- 6.1.1. Aluminum

- 6.1.2. Titanium

- 6.1.3. Tantalum

- 6.1.4. Copper

- 6.1.5. Others

- 6.2. Market Analysis, Insights and Forecast - by Application

- 6.2.1. Semiconductor

- 6.2.2. Flat Panel Display Panel

- 6.2.3. Thin Film Solar Cell

- 6.2.4. Storage Media

- 6.1. Market Analysis, Insights and Forecast - by Type

- 7. South America Sputtering Coating Pure Metal Material Analysis, Insights and Forecast, 2019-2031

- 7.1. Market Analysis, Insights and Forecast - by Type

- 7.1.1. Aluminum

- 7.1.2. Titanium

- 7.1.3. Tantalum

- 7.1.4. Copper

- 7.1.5. Others

- 7.2. Market Analysis, Insights and Forecast - by Application

- 7.2.1. Semiconductor

- 7.2.2. Flat Panel Display Panel

- 7.2.3. Thin Film Solar Cell

- 7.2.4. Storage Media

- 7.1. Market Analysis, Insights and Forecast - by Type

- 8. Europe Sputtering Coating Pure Metal Material Analysis, Insights and Forecast, 2019-2031

- 8.1. Market Analysis, Insights and Forecast - by Type

- 8.1.1. Aluminum

- 8.1.2. Titanium

- 8.1.3. Tantalum

- 8.1.4. Copper

- 8.1.5. Others

- 8.2. Market Analysis, Insights and Forecast - by Application

- 8.2.1. Semiconductor

- 8.2.2. Flat Panel Display Panel

- 8.2.3. Thin Film Solar Cell

- 8.2.4. Storage Media

- 8.1. Market Analysis, Insights and Forecast - by Type

- 9. Middle East & Africa Sputtering Coating Pure Metal Material Analysis, Insights and Forecast, 2019-2031

- 9.1. Market Analysis, Insights and Forecast - by Type

- 9.1.1. Aluminum

- 9.1.2. Titanium

- 9.1.3. Tantalum

- 9.1.4. Copper

- 9.1.5. Others

- 9.2. Market Analysis, Insights and Forecast - by Application

- 9.2.1. Semiconductor

- 9.2.2. Flat Panel Display Panel

- 9.2.3. Thin Film Solar Cell

- 9.2.4. Storage Media

- 9.1. Market Analysis, Insights and Forecast - by Type

- 10. Asia Pacific Sputtering Coating Pure Metal Material Analysis, Insights and Forecast, 2019-2031

- 10.1. Market Analysis, Insights and Forecast - by Type

- 10.1.1. Aluminum

- 10.1.2. Titanium

- 10.1.3. Tantalum

- 10.1.4. Copper

- 10.1.5. Others

- 10.2. Market Analysis, Insights and Forecast - by Application

- 10.2.1. Semiconductor

- 10.2.2. Flat Panel Display Panel

- 10.2.3. Thin Film Solar Cell

- 10.2.4. Storage Media

- 10.1. Market Analysis, Insights and Forecast - by Type

- 11. Competitive Analysis

- 11.1. Global Market Share Analysis 2024

- 11.2. Company Profiles

- 11.2.1 TANAKA HOLDINGS Co. Ltd

- 11.2.1.1. Overview

- 11.2.1.2. Products

- 11.2.1.3. SWOT Analysis

- 11.2.1.4. Recent Developments

- 11.2.1.5. Financials (Based on Availability)

- 11.2.2 Honeywell

- 11.2.2.1. Overview

- 11.2.2.2. Products

- 11.2.2.3. SWOT Analysis

- 11.2.2.4. Recent Developments

- 11.2.2.5. Financials (Based on Availability)

- 11.2.3 JX Advanced Metals Corporation

- 11.2.3.1. Overview

- 11.2.3.2. Products

- 11.2.3.3. SWOT Analysis

- 11.2.3.4. Recent Developments

- 11.2.3.5. Financials (Based on Availability)

- 11.2.4 Tosoh

- 11.2.4.1. Overview

- 11.2.4.2. Products

- 11.2.4.3. SWOT Analysis

- 11.2.4.4. Recent Developments

- 11.2.4.5. Financials (Based on Availability)

- 11.2.5 Praxair

- 11.2.5.1. Overview

- 11.2.5.2. Products

- 11.2.5.3. SWOT Analysis

- 11.2.5.4. Recent Developments

- 11.2.5.5. Financials (Based on Availability)

- 11.2.6 Solar Applied Materials Technology Corp

- 11.2.6.1. Overview

- 11.2.6.2. Products

- 11.2.6.3. SWOT Analysis

- 11.2.6.4. Recent Developments

- 11.2.6.5. Financials (Based on Availability)

- 11.2.7 Sumitomo Chemical

- 11.2.7.1. Overview

- 11.2.7.2. Products

- 11.2.7.3. SWOT Analysis

- 11.2.7.4. Recent Developments

- 11.2.7.5. Financials (Based on Availability)

- 11.2.8 H.C. Starck Tungsten Powders

- 11.2.8.1. Overview

- 11.2.8.2. Products

- 11.2.8.3. SWOT Analysis

- 11.2.8.4. Recent Developments

- 11.2.8.5. Financials (Based on Availability)

- 11.2.9 Materion

- 11.2.9.1. Overview

- 11.2.9.2. Products

- 11.2.9.3. SWOT Analysis

- 11.2.9.4. Recent Developments

- 11.2.9.5. Financials (Based on Availability)

- 11.2.10 Ulvac Materials

- 11.2.10.1. Overview

- 11.2.10.2. Products

- 11.2.10.3. SWOT Analysis

- 11.2.10.4. Recent Developments

- 11.2.10.5. Financials (Based on Availability)

- 11.2.11 Fujian Acetron New

- 11.2.11.1. Overview

- 11.2.11.2. Products

- 11.2.11.3. SWOT Analysis

- 11.2.11.4. Recent Developments

- 11.2.11.5. Financials (Based on Availability)

- 11.2.12 Konfoong Materials International Co Ltd

- 11.2.12.1. Overview

- 11.2.12.2. Products

- 11.2.12.3. SWOT Analysis

- 11.2.12.4. Recent Developments

- 11.2.12.5. Financials (Based on Availability)

- 11.2.13 Grinm Semiconductor Materials Co. Ltd

- 11.2.13.1. Overview

- 11.2.13.2. Products

- 11.2.13.3. SWOT Analysis

- 11.2.13.4. Recent Developments

- 11.2.13.5. Financials (Based on Availability)

- 11.2.14 LONGHUA TECHNOLOGY GROUP LUOYANG CO LTD

- 11.2.14.1. Overview

- 11.2.14.2. Products

- 11.2.14.3. SWOT Analysis

- 11.2.14.4. Recent Developments

- 11.2.14.5. Financials (Based on Availability)

- 11.2.1 TANAKA HOLDINGS Co. Ltd

- Figure 1: Global Sputtering Coating Pure Metal Material Revenue Breakdown (million, %) by Region 2024 & 2032

- Figure 2: North America Sputtering Coating Pure Metal Material Revenue (million), by Type 2024 & 2032

- Figure 3: North America Sputtering Coating Pure Metal Material Revenue Share (%), by Type 2024 & 2032

- Figure 4: North America Sputtering Coating Pure Metal Material Revenue (million), by Application 2024 & 2032

- Figure 5: North America Sputtering Coating Pure Metal Material Revenue Share (%), by Application 2024 & 2032

- Figure 6: North America Sputtering Coating Pure Metal Material Revenue (million), by Country 2024 & 2032

- Figure 7: North America Sputtering Coating Pure Metal Material Revenue Share (%), by Country 2024 & 2032

- Figure 8: South America Sputtering Coating Pure Metal Material Revenue (million), by Type 2024 & 2032

- Figure 9: South America Sputtering Coating Pure Metal Material Revenue Share (%), by Type 2024 & 2032

- Figure 10: South America Sputtering Coating Pure Metal Material Revenue (million), by Application 2024 & 2032

- Figure 11: South America Sputtering Coating Pure Metal Material Revenue Share (%), by Application 2024 & 2032

- Figure 12: South America Sputtering Coating Pure Metal Material Revenue (million), by Country 2024 & 2032

- Figure 13: South America Sputtering Coating Pure Metal Material Revenue Share (%), by Country 2024 & 2032

- Figure 14: Europe Sputtering Coating Pure Metal Material Revenue (million), by Type 2024 & 2032

- Figure 15: Europe Sputtering Coating Pure Metal Material Revenue Share (%), by Type 2024 & 2032

- Figure 16: Europe Sputtering Coating Pure Metal Material Revenue (million), by Application 2024 & 2032

- Figure 17: Europe Sputtering Coating Pure Metal Material Revenue Share (%), by Application 2024 & 2032

- Figure 18: Europe Sputtering Coating Pure Metal Material Revenue (million), by Country 2024 & 2032

- Figure 19: Europe Sputtering Coating Pure Metal Material Revenue Share (%), by Country 2024 & 2032

- Figure 20: Middle East & Africa Sputtering Coating Pure Metal Material Revenue (million), by Type 2024 & 2032

- Figure 21: Middle East & Africa Sputtering Coating Pure Metal Material Revenue Share (%), by Type 2024 & 2032

- Figure 22: Middle East & Africa Sputtering Coating Pure Metal Material Revenue (million), by Application 2024 & 2032

- Figure 23: Middle East & Africa Sputtering Coating Pure Metal Material Revenue Share (%), by Application 2024 & 2032

- Figure 24: Middle East & Africa Sputtering Coating Pure Metal Material Revenue (million), by Country 2024 & 2032

- Figure 25: Middle East & Africa Sputtering Coating Pure Metal Material Revenue Share (%), by Country 2024 & 2032

- Figure 26: Asia Pacific Sputtering Coating Pure Metal Material Revenue (million), by Type 2024 & 2032

- Figure 27: Asia Pacific Sputtering Coating Pure Metal Material Revenue Share (%), by Type 2024 & 2032

- Figure 28: Asia Pacific Sputtering Coating Pure Metal Material Revenue (million), by Application 2024 & 2032

- Figure 29: Asia Pacific Sputtering Coating Pure Metal Material Revenue Share (%), by Application 2024 & 2032

- Figure 30: Asia Pacific Sputtering Coating Pure Metal Material Revenue (million), by Country 2024 & 2032

- Figure 31: Asia Pacific Sputtering Coating Pure Metal Material Revenue Share (%), by Country 2024 & 2032

- Table 1: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Region 2019 & 2032

- Table 2: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Type 2019 & 2032

- Table 3: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Application 2019 & 2032

- Table 4: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Region 2019 & 2032

- Table 5: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Type 2019 & 2032

- Table 6: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Application 2019 & 2032

- Table 7: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Country 2019 & 2032

- Table 8: United States Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 9: Canada Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 10: Mexico Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 11: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Type 2019 & 2032

- Table 12: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Application 2019 & 2032

- Table 13: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Country 2019 & 2032

- Table 14: Brazil Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 15: Argentina Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 16: Rest of South America Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 17: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Type 2019 & 2032

- Table 18: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Application 2019 & 2032

- Table 19: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Country 2019 & 2032

- Table 20: United Kingdom Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 21: Germany Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 22: France Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 23: Italy Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 24: Spain Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 25: Russia Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 26: Benelux Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 27: Nordics Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 28: Rest of Europe Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 29: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Type 2019 & 2032

- Table 30: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Application 2019 & 2032

- Table 31: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Country 2019 & 2032

- Table 32: Turkey Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 33: Israel Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 34: GCC Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 35: North Africa Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 36: South Africa Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 37: Rest of Middle East & Africa Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 38: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Type 2019 & 2032

- Table 39: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Application 2019 & 2032

- Table 40: Global Sputtering Coating Pure Metal Material Revenue million Forecast, by Country 2019 & 2032

- Table 41: China Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 42: India Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 43: Japan Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 44: South Korea Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 45: ASEAN Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 46: Oceania Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

- Table 47: Rest of Asia Pacific Sputtering Coating Pure Metal Material Revenue (million) Forecast, by Application 2019 & 2032

| Aspects | Details |

|---|---|

| Study Period | 2019-2033 |

| Base Year | 2024 |

| Estimated Year | 2025 |

| Forecast Period | 2025-2033 |

| Historical Period | 2019-2024 |

| Growth Rate | CAGR of 8.8% from 2019-2033 |

| Segmentation |

|

STEP 1 - Identification of Relevant Samples Size from Population Database

STEP 2 - Approaches for Defining Global Market Size (Value, Volume* & Price*)

Note* : In applicable scenarios

STEP 3 - Data Sources

Primary Research

- Web Analytics

- Survey Reports

- Research Institute

- Latest Research Reports

- Opinion Leaders

Secondary Research

- Annual Reports

- White Paper

- Latest Press Release

- Industry Association

- Paid Database

- Investor Presentations

STEP 4 - Data Triangulation

Involves using different sources of information in order to increase the validity of a study

These sources are likely to be stakeholders in a program - participants, other researchers, program staff, other community members, and so on.

Then we put all data in single framework & apply various statistical tools to find out the dynamic on the market.

During the analysis stage, feedback from the stakeholder groups would be compared to determine areas of agreement as well as areas of divergence

Related Reports

About Market Research Forecast

MR Forecast provides premium market intelligence on deep technologies that can cause a high level of disruption in the market within the next few years. When it comes to doing market viability analyses for technologies at very early phases of development, MR Forecast is second to none. What sets us apart is our set of market estimates based on secondary research data, which in turn gets validated through primary research by key companies in the target market and other stakeholders. It only covers technologies pertaining to Healthcare, IT, big data analysis, block chain technology, Artificial Intelligence (AI), Machine Learning (ML), Internet of Things (IoT), Energy & Power, Automobile, Agriculture, Electronics, Chemical & Materials, Machinery & Equipment's, Consumer Goods, and many others at MR Forecast. Market: The market section introduces the industry to readers, including an overview, business dynamics, competitive benchmarking, and firms' profiles. This enables readers to make decisions on market entry, expansion, and exit in certain nations, regions, or worldwide. Application: We give painstaking attention to the study of every product and technology, along with its use case and user categories, under our research solutions. From here on, the process delivers accurate market estimates and forecasts apart from the best and most meaningful insights.

Products generically come under this phrase and may imply any number of goods, components, materials, technology, or any combination thereof. Any business that wants to push an innovative agenda needs data on product definitions, pricing analysis, benchmarking and roadmaps on technology, demand analysis, and patents. Our research papers contain all that and much more in a depth that makes them incredibly actionable. Products broadly encompass a wide range of goods, components, materials, technologies, or any combination thereof. For businesses aiming to advance an innovative agenda, access to comprehensive data on product definitions, pricing analysis, benchmarking, technological roadmaps, demand analysis, and patents is essential. Our research papers provide in-depth insights into these areas and more, equipping organizations with actionable information that can drive strategic decision-making and enhance competitive positioning in the market.